Flexible Optics: Phone-based optical lead testing exceeds EPA standards

Among technologists who responded with innovation to the devastating 2014 discovery of lead in the Flint, MI water supply (and subsequent discoveries by other municipalities) is a group of researchers at the University of Houston (Houston, TX), who devised a portable, inexpensive, and easy-to-use optical system that exceeds EPA detection standards in detecting lead contaminants in water.1

Detecting lead (Pb2+) in water is typically a time-consuming process requiring laboratories and bulky and costly analytical instruments. The researchers’ low-cost smartphone-based nanocolorimetry (SNC) enables individuals to quickly quantify Pb2+ content in drinking water themselves in virtually any setting. Their SNC system is a self-contained microscope—including an inexpensive Lumina 640 smartphone and an 8 Mpixel camera—that operates in both fluorescence and dark-field imaging modes.

The essential lens

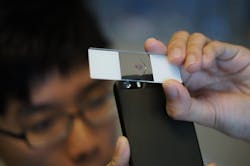

Because the microscopy capability is what allows the system to detect low levels of lead, a key feature of the system is its inexpensive, inkjet-printed elastomer optical lens. It attaches to a basic smartphone camera without accessories and produces high-resolution (1 μm) microscope images.

The lens is a discovery made years earlier by researchers in the lab of Wei-Chuan Shih, associate professor of electrical & computer engineering.2 The group’s highly repeatable, lithography-free, and mold-free method enables production of flexible optical lenses by placing liquid polydimethylsiloxane (PDMS) droplets on a preheated surface. The researchers discovered that they could control focal length by varying droplet volume and surface temperature and proved the ability to create lenses with a focal length as short as 5.6 mm.

In 2017, Biomedical Optics Express published its most frequently downloaded paper: an open-source design from Shih’s team that explains how the lens can turn a smartphone into a fluorescence microscope.3 The produced lens, called DotLens (www.dotlens.net), is made from a patent-pending rubber-derived optopolymer that allows it to securely attach to any smartphone or tablet camera (a bit like a contact lens, without glue or attachments), and to be removed just as easily without leaving residue. It is scratch-resistant and can be reused repeatedly without losing its ability to adhere. Now, DotLens is produced with a 3D printing system that leaves the lenses free of layering defects typical for extrusion-type 3D printers.

Exceeding standards

According to the World Health Organization, no amount of lead exposure is considered safe. Even small amounts can produce serious health problems, and lead is particularly harmful to young children. EPA standards require drinking water to test at less than 15 parts per billion (ppb), but according to Shih, test kits currently sold to consumers aren’t sufficiently sensitive to detect lead concentrations at that level. By contrast, the researchers’ dark-field imaging mode proved able to detect lead at 5 ppb in tap water and 1.37 ppb in deionized water (see figure).

Applying their 2017 dataset, the researchers used a single-step sedimentation approach to detect and quantify the Pb2+ in water. They dissolved varying amounts of Pb2+ (1.37–175 ppb) in tap water and added chromate ions (CrO42–), which react with Pb2+ to produce highly insoluble lead chromate (PbCrO4) nanoparticles. The system proved able to detect the resulting vivid yellow PbCrO4 precipitates, and the researchers discovered that the sum of the yellow pixels’ intensity has a highly reproducible relationship with Pb2+ concentration (5–175 ppb in tap water, and 1.37–175 ppb in deionized water).

Because the quantity of sediment was too small for imaging by an unaided smartphone camera, the lens was essential for detecting relatively low levels of lead. And whereas traditional colorimetric techniques analyze bulk color changes, the SNC device produces superior sensitivity through nanocolorimetry and dark-field microscopy.

REFERENCES

1. H. Nguyen et al., Anal. Chem., 90, 19, 11517–11522 (2018).

2. Y. Sung et al., J. Biomed. Opt., 20, 4, 047005 (2015).

3. Y. Sung et al., Biomed. Opt. Express, 8, 11, 5075–5086 (2017).

About the Author

Barbara Gefvert

Editor-in-Chief, BioOptics World (2008-2020)

Barbara G. Gefvert has been a science and technology editor and writer since 1987, and served as editor in chief on multiple publications, including Sensors magazine for nearly a decade.