Optical Fiber Manufacturing: Gravity-free optical fiber manufacturing breaks Earthly limitations

HARRISON PITMAN

The optical fiber used to connect continents is made from silica glass. Though silica fibers are the industry standard for telecommunications cables, the material is limited by its narrow transmission window and the need for repeaters to amplify the light source. Other fibers such as ZBLAN have been theorized to perform better than silica, but terrestrial manufacturing challenges have historically made these fibers infeasible for telecommunications applications.

With the limitations of silica fiber being well understood, improvements are continually being made to the fiber available for underwater cables. However, to address the increasing global demand for Internet usage, which is approaching the upper limit of what the current infrastructure can support, other materials are being considered for subsea telecommunication lines. These alternatives may not be subject to the same limitations as silica fibers, especially if the confines of standard draw-tower manufacturing are removed.1

Silica fiber alternatives

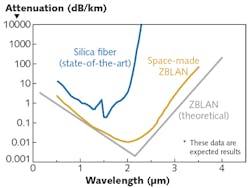

Rare-earth-doped zirconium fluoride/barium fluoride/lanthanum fluoride/aluminum fluoride/sodium fluoride (ZrF4-BaF2-LaF3-AlF3-NaF) or ZBLAN optical fiber has a broad transmission window, optimally transmitting at 2200 nm, and significantly lower attenuation than silica fiber at standard 1310 and 1550 nm telecommunications wavelengths (see Fig. 1).

The compounds which comprise ZBLAN vary greatly in density, giving the material attractive properties across the near-to-mid infrared spectrum. Because of its unique composition of heavy metal fluoride compounds, ZBLAN is formed as a crystalline lattice. This lattice, however, cannot form properly in Earth’s gravity, creating significant barriers to its potential as a commercial telecommunications fiber and limiting production to small quantities for specialty applications. Despite these barriers, ZBLAN fiber is still used in lasers, endoscopy and spectroscopy equipment, supercontinuum light sources, and advanced optics and sensors.

There are two types of losses that restrict ZBLAN from more closely approaching its theoretical potential: absorption losses caused by impurities in the glass as a preform, and scattering losses caused by small microcrystals that form when the glass is manufactured in a gravity-rich environment. While ZBLAN experts Thorlabs (Newton, NJ) have addressed absorption losses through the creation of ultra-pure preforms, scattering losses can only be addressed by pulling the fiber in microgravity.

If ZBLAN could be manufactured to perform better than silica fiber, the planet’s available data-throughput infrastructure could grow at a faster pace, ensuring that the world stay connected as the number of Internet users and Internet-enabled devices continues to grow exponentially.

Microgravity manufacturing

Made In Space (MIS) is a manufacturing company with the goal of enabling people to live and work in space. By developing and deploying space-ready manufacturing systems, we are developing solutions for industry and government to meet the manufacturing needs of the future.

In 2010, MIS began developing zero-gravity 3D printers for the International Space Station (ISS). In developing manufacturing hardware for space, MIS is constantly making new discoveries about how materials behave in the microgravity environment. Microgravity, high radiation, extreme temperature, and extreme pressure environments are normal challenges that we face when designing systems for space. Despite these challenges, space is actually the optimal environment for processing certain materials.

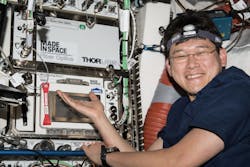

MIS owns and operates the world’s only commercial manufacturing facility off Earth—the Additive Manufacturing Facility (AMF). The first commercially available 3D printer in space, AMF is changing the paradigm of delivering assets to space, as it has been used by doctors, researchers, universities, and space explorers to further mission lifecycles, evaluate the feasibility of 3D printing medical devices in remote areas, and create satellites in space (see Fig. 2).Since development of its first 3D printers, MIS has also advanced several other technologies from space robots to material recyclers, enabling the future of deep-space missions and supporting the development of a Low Earth Orbit economy.

Extensive research has been performed on the effects of ZBLAN when processed in a microgravity environment. Interested in ZBLAN’s benefits, the National Aeronautics and Space Administration (NASA; Washington, DC) carried out a series of experiments in the 1990s that sought to better understand the role that gravity plays in the composition of the material. In 1994, NASA researchers heated terrestrially produced ZBLAN onboard a KC-135 flying microgravity parabolas. It was observed that none of the noncontaminated samples that were processed in microgravity showed signs of new crystal formations.2

In 1996, NASA attempted again to test the effects of microgravity on ZBLAN processing, but poor design of the experiment allowed the fiber to be exposed to water, effectively destroying the material used in the experiment. Three samples remained intact, none of which had gravity-induced crystallization present.3 Together, these experiments demonstrated that crystallization is suppressed in ZBLAN when processed in microgravity (see Fig. 4).

Although the experiments did provide conclusive evidence of crystal suppression in microgravity, the very limited duration of microgravity on these test flights did not allow researchers to quantify the performance improvements. Additional experiments need be done on a persistent microgravity platform that will allow researchers to produce longer, quantitatively testable lengths of fiber.

On Earth, ZBLAN is made in tall draw towers that can range from 3 m to three stories tall. The process involves using gravity to begin to pull a section of the heated preform until it achieves the correct diameter of drawn fiber. Several components contribute to a successful fiber pull, such as the temperature of the furnace, the uniformity of heating, the angle of the preform as it heats, and the speed at which the fiber is pulled. Sensors, motors, and actuators ensure that every aspect of the system is functioning correctly, from first heating up the preform to spooling the fiber.

To begin adapting the manufacturing process for space, MIS sought a partnership with Thorlabs. Thorlabs showed MIS the intricacies of drop tower manufacturing, and the companies began work on shrinking the process down to work in a microwave oven-sized device, as space is limited on the ISS. In addition to significantly reducing the size of the entire system, the MIS Fiber Optics payload needed to be completely autonomous, as devices on the ISS cannot viably rely on seldom and expensive astronaut labor. When the device leaves Earth on a rocket, it is sealed, not to be opened again until it returns to Earth.Because the fiber will be ruined if it contacts any amount of water, MIS developed a completely enclosed system with a custom environmental control unit that maintains an optimal manufacturing environment within the payload. Once the unit arrives to the ISS, the astronauts unstow the device, attach its power and data connections, and it is then commanded from the MIS Mission Control Center in Moffett Field, CA.

The device stows ultra-pure Thorlabs preforms inside, relying on internal robotics to correctly position the preforms and spool the fiber. After all preforms have been processed into space-enabled fiber, the device is disconnected from power and data and re-stowed on an entry capsule before returning to Earth.

Space-enabled fiber

Made In Space has two core objectives in manufacturing space-enabled fiber. The first is to demonstrate that space-enabled fiber can be efficiently manufactured on the ISS. Crewtime is limited and many experiments are being conducted simultaneously, so it is pivotal for the MIS Fiber Optics payload to not rely on active human involvement. The second is to produce long-enough quantities of ZBLAN that the material improvements can be quantitatively characterized.

The first fiber-optic manufacturing device from MIS was sent to the ISS in December 2017. Since then, there have been three additional fiber-optics missions to the ISS, each sending a unit after the preceding unit returns. The most recent launch took place in November 2018, with several more launches manifested in 2019. The company is actively working with Thorlabs and other partners to understand the full material benefits and advantages of space-produced ZBLAN.

REFERENCES

1. I. Cozmuta and D. J. Rasky, New Space, 5, 3, 121–140 (Sep. 1, 2017).

2. See http://bit.ly/lfwpdf1.

3. See http://bit.ly/lfwpdf2.

Harrison Pitman is product developer at Made In Space, Moffett Field, CA; e-mail: [email protected]; http://madeinspace.us.