Diode Lasers: Direct and frequency-converted diode lasers provide all wavelengths for holography

ULRICH EISMANN and TIM PAASCH-COLBERG

When Dennis Gábor tried to improve electron microscope resolution at the end of the 1940s, he probably did not realize what impact his work would have. He discovered the holographic method that enables the display of a full three-dimensional (3D) image of an object. Combined with the invention of the laser, holography left the research labs and turned into a billion-dollar business with a multitude of applications.

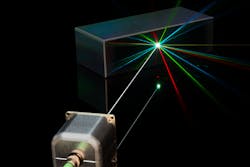

Today’s practical applications of holography range from the well-known security holograms on credit cards, bank notes, and passports, through to medical holography. Optical components like transmission or reflection gratings find a multitude of applications in lasers or spectrometers (see image above).

Microintegration of these components has advanced very far, examples being the distributed feedback (DFB) and distributed Bragg reflector (DBR) laser diodes, or fiber Bragg gratings. In the near future, significant growth of the sector is expected from the market introduction of augmented reality devices.

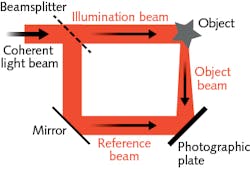

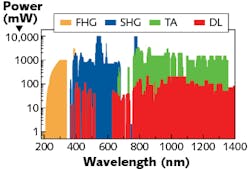

The principles of optical holography have not changed significantly since it was first invented (see Fig. 1). A beamsplitter is used to divide a laser beam into two parts—the illumination beam that irradiates the object and the reference beam that is sent directly to a recording medium (typically, a photographic plate). The reference beam interferes with the illumination light reflected by the object, and the resulting interference pattern is recorded in a photosensitive substrate. After this procedure, the substrate can be illuminated to produce a 3D image of the object.Figure 2 illustrates this extended spectral coverage, which shows the output power as a function of the emission wavelength of Toptica’s tunable diode lasers. The spectrum reaches from the deep-UV (190 nm) to mid-IR (3500 nm) wavelength range, with output power levels of up to several Watts. It includes red-green-blue (RGB) wavelengths around 457, 532, and 647 nm (see table). For extremely power-hungry applications, the tapered-amplifier (TA) semiconductor gain chip can be replaced by a fiber amplifier such as that used in our SodiumStar laser, which provides 22 W output power at 589 nm, creating artificial guide stars for telescopes.2

Available output powers from Toptica at popular holography wavelengths | |

Laser wavelength | Output power |

193 nm | 0.1 mW |

213 nm | 10 mW |

266 nm | 300 mW |

405 nm | 800 mW |

457–462 nm* | 500 mW |

525–535 nm* | 500 mW |

633 nm | 500 mW |

645–655 nm* | 500 mW |

*Tuning option available | |

The resolution of the interference pattern is important to shape ever-smaller lithographic features used in electronic devices. This in turn requires ever-shorter laser wavelengths. Reaching far into the UV, gas lasers have set a few standard wavelengths that are used widely in holography and (incoherent) lithography. Thus, because of their straightforward handling, excellent beam parameters, and lower operational cost, diode lasers have found their way into applications that were formerly dominated by gas lasers.

For example, krypton ion lasers emitting at 407 nm have been replaced by 405 nm diode lasers for several years now. This replacement is achieved either by using direct diodes or, if Watt-class power is required, by frequency-doubling of a powerful, stable, and narrowband IR lasers. The UV range is reached by adding another stage of frequency-conversion. The popular 266 nm wavelength applications are served by lasers offering coherent output power of 300 mW with near diffraction-limited beam quality (typically M2 < 1.2).

Driving applications of holography

The manufacturing process of dedicated optical semiconductors requires holographic generation of gratings inside the material. This is typically done using frequency-converted gas or diode lasers at 244 nm. The popular 213 nm wavelength from frequency-quintupled pulsed Nd:YAG lasers can be provided in high-power continuous-wave operation from diode lasers, including all the functionality presented here.

A further crucial advancement towards even shorter wavelengths is the use of potassium beryllium fluoroborate (KBBF) crystals as frequency-doubling medium. These allow holography at the popular 193 nm wavelength with diode lasers instead of excimer lasers.3

Augmented reality (AR) devices like Microsoft’s Hololens are examples of an emerging consumer application of holography. AR has the potential to completely shift the pace of the workplace and can potentially replace smartphones. A similar mass-market application is in the automotive sector, where important driver information such as the current speed of the vehicle can be projected directly “on the road” using a head-up display. In both applications, holographic imaging devices feature the best simultaneous brightness of both the ambient light and of the projected image. Therefore, users experience a true immersion into their augmented reality.

Since illumination LEDs or laser diodes have an emission wavelength that is scattered by a few nanometers around the design wavelength, the image projection result can be very dim or even invisible. Here, another advantage of diode lasers comes into play, which is the possibility to tune the writing laser to the emission wavelength of choice. This accounts for the flaws of the device’s illumination source before writing the hologram.

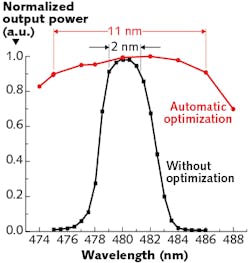

Figure 3 shows an example of such a tuning curve, where 14 nm of automatic tuning around 480 nm is demonstrated. The non-optimized diode laser tunes over 2 nm across the set wavelength before the power drops below 90% of the peak power. The automatically optimized diode laser tunes over 11 nm before the 90% criterion is met, which results in a five-fold increase of the useful tuning range.These diode laser systems are inherently efficient, typically consuming <100 W of electrical power. This means savings of hundreds of thousands of kilowatt hours compared to more power-hungry gas lasers. In addition, they operate without water cooling, which not only simplifies setup and operation of the laser, but lowers the already significantly reduced cost of ownership. Since the heat intake of a holography lab is a crucial element and air turbulence or acoustic noise can make a holographic recording unusable, diode lasers can be made to operate with passive cooling and without fans.

Serviceability is provided by cost-effective field-replaceable units (FRUs), which mostly consist of compact optical semiconductor sub-components.

Keeping coherence

Coherence length is a crucial parameter of a holography light source. In principle, the coherence length must at least equal the path length difference between illumination and reference beams to enable their interference at the photographic plate.

Operating on a single frequency, tunable diode lasers can offer coherence lengths beyond 100 m in their standard configuration. In addition, the locking electronics can allow locking two lasers in phase. This way, the reference beam can also be generated directly at the medium using a second laser.

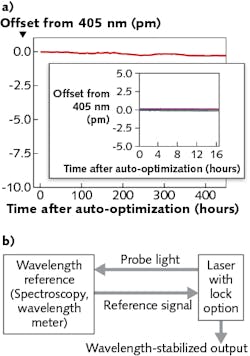

In some applications, absolute wavelength and stability are critical. Without additional arrangements, the output wavelength of a free-running diode laser shows residual drifts. These drifts can be strongly suppressed using built-in air pressure compensation (see Fig. 4a). Because of the absence of cooling water, the amount of high-frequency wavelength jitter is negligible.If an absolute wavelength reference is needed, a spectroscopy module can be connected to the system. For example, absolutely referenced systems at 390.1 nm and 397.5 nm, provided by the D-lines of a gas of rubidium atoms have been realized (see Fig. 4b). This principle is transferrable to all wavelengths by replacing the reference gas cell by a wavelength meter with all-digital wavelength locking functionality.

As presented above, diode lasers fulfill the technical requirements to perform holography and lithography applications not only at established wavelengths, but also at all wavelengths in the UV and visible range. In combination with the non-technical advantages compared to traditional lasers, especially in handling, operation, and cost of ownership, diode lasers are clearly a very attractive laser source for holography.

REFERENCES

1. U. Eismann et al., “Short, shorter, shortest: Diode lasers in the deep ultraviolet,” Laser Focus World, 52, 6, 39–44 (2016); see https://goo.gl/Ys9SRm.

2. B. Ernstberger et al., “Robust remote-pumping sodium laser for advanced LIDAR and guide star applications,” Proc. SPIE, 9641, 96410F (2015).

3. M. Scholz et al., Appl. Phys. Lett., 103, 051114 (2013).

4. U. Eismann et al., “Active and passive stabilization of a high-power violet frequency-doubled diode laser,” CLEO 2016, JTu5A.65 (2016).

Ulrich Eismann is product manager, NLO diode lasers and Tim Paasch-Colberg is director of marketing, both at Toptica Photonics, Munich, Germany; e-mail: ulrich.eismann@toptica.com; www.toptica.com.