Real-time detector for IV drugs could prevent life-threatening medical errors

Computerized smart systems can deliver drugs intravenously in exact volumes to hospital patients, but cannot recognize which medications are in the tubing nor determine the concentration of the drug in the tubing. This lack of precise information can lead to medication errors with serious consequences.

Recognizing this, a team of electrical and computer engineering students at the University of Illinois at Urbana-Champaign (UIUC) has developed a new optical device that can identify the contents of the fluid in an intravenous (IV) line in real time, offering a promising way to improve the safety of IV drug delivery.

The vulnerability of IV drug-delivery systems due to human error is a chief concern in hospital safety, explains Prof. Brian T. Cunningham, interim director of the Micro and Nanotechnology Laboratory at UIUC, who led the work. Errors can include incorrect dosage, unintentional substitution of one drug for another, and co-delivery of incompatible drugs.

"Up to 61 percent of all life-threatening errors during hospitalization are associated with IV drug therapy,â Cunningham says, citing a recent report. âSo for all the really good things hospitals can do, the data shows that mistakes can occasionally happen."

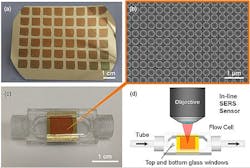

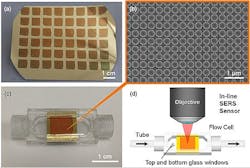

To approach this problem, the research team turned to structures and processes at the nanoscale, where novel physical and chemical properties arise. They used a technology called surface-enhanced Raman scattering (SERS), which has extreme sensitivity in obtaining molecular signals that can be used to identify chemicals. To determine the identity of a particular IV medication, the researchers shone laser light onto a nanostructured gold surface that contained millions of tiny ânano-domesâ that are separated from each other by as little as 10 nm. The nano-domes were incorporated into the inner surface of IV tubing, where they were exposed to drugs dispersed in liquid. They captured the light scattered from drug molecules in contact with the nano-domes and used SERS to determine the drugâs molecular signature. Finally, they matched the signature to known signatures for the drug in order to confirm the presence of a specific medication in the IV line.

While other groups have demonstrated excellent nanostructured surfaces for SERS, those developed by the Cunningham group are unique because they are inexpensively produced on flexible plastic surfaces by a replica molding process with nanometer-scale accuracy.

Early data show that the Cunningham groupâs system can identify medications including morphine, methadone, phenobarbital, the sedative promethazine, and mitoxantrone, which is used to treat multiple sclerosis. The system can detect drugs in amounts 100 times lower than the clinically delivered drug concentrations commonly used. So far, the researchers have also shown that their system can sense a two-drug combination, which has its own unique signature.

The next step is further evaluation for combinations of up to 10 drugs being delivered at the same time. Computer algorithms are also being developed to automatically interpret the SERS spectra, and Cunninghamâs team reports that the system is now being evaluated for possible commercialization.

The research team will present its work during The Optical Societyâs (OSA's) Frontiers in Optics (FiO) 2013 meeting in Orlando, FL, on Thursday, October 10, at 2:30 pm (EST) at the Hilton Bonnet Creek (presentation LTh3H.4, âPoint-of-care Detection and Real-time Monitoring of Intravenously Delivered Drugs via Tubing with an Integrated SERS Sensorâ).

-----

Follow us on Twitter, 'like' us on Facebook, and join our group on LinkedIn

Subscribe now to BioOptics World magazine; it's free!