OPTICAL FIBER FOR MEDICAL APPLICATIONS: Improved deep-UV fiber for medical and spectroscopy applications

John Shannon

Fiber used in biomedical applications must not only be safe, sterile, and robust enough for autoclaving, but also highly stable and reliable to ensure accurate diagnostics and, most importantly, safety for patients. The unique characteristics of deep-ultraviolet (deep-UV) fiber help enable advanced biomedical diagnostic equipment, including patient diagnostics, instruments for minimally invasive surgical procedures, and sensors attached directly to the body for monitoring purposes.

A majority of fiber used in spectroscopy is used for material and optical sensing in the mid-UV range down to 190 nm. Many biomedical sensing applications require optical fibers that transmit light in the UV region. Within the industry, demand is rising for laser and other biomedical equipment using deep-UV fiber. Such fiber is suitable for laser delivery in eye surgery, plastic surgery, urology, and other procedures requiring a combination of UV light and smaller-core-diameter fiber.

Solarization risk in DUV fibers

The pure silica core material used in step-index optical fibers is susceptible to UV-induced attenuation, also known as solarization. This increase in attenuation is caused by the increase in localized defect centers in the glass structure produced by exposure to UV radiation. Most of the attenuation occurs at wavelengths <275 nm, especially in the absorption bands at 214 and 265 nm.

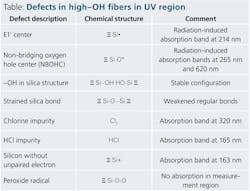

The degree of damage varies greatly with the type of fiber. For example, synthetic fused silica used as the core material in common step-index optical fibers is an extremely pure material. However, several intrinsic and impurity defects are present in varying concentrations; in addition, certain defects in the silica structure can be caused by incident UV radiation. The concentration of each defect is dependent on several factors, including contaminants from the preform fabrication process, preform fabrication technique, and fiber-draw process (see Table for a summary of defect types).

For the spectral region of 190 to 300 nm, the primary defects of greatest concern are E1' centers and nonbridging oxygen hole centers (NBOHCs). These two defects are responsible for the induced attenuation at 214 and 265 nm, respectively. We have created optimized fiber with improved performance achieved primarily by reducing the distribution of these two defects.

Pre-existing developments in UV fiber

The stability of deep-UV transmission is an important parameter in optical-system design, especially in high-performance spectroscopy applications. Historically, fibers with high hydroxide anion (OH-) content have been used for wavelengths shorter than 400 nm. Over the years, many types of UV fibers have been developed to minimize the effects of solarization. Solarization resistance has been improved by optimizing various aspects of the fiber, including preform design and postprocessing of the drawn fiber. The following are representative fibers, as produced by Polymicro:

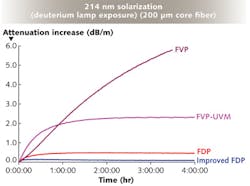

FVP – This standard UV/visible fiber uses a high OH- pure silica core preform that has not been optimized for solarization resistance. This fiber is very sensitive to solarization.

UVM – This fiber is made with a preform having high OH- silica core material optimized to reduce the defect content.

UVMI – This fiber is drawn using the same preform used in UVM fiber; following the draw process, the fiber is loaded with dissolved hydrogen at elevated temperature and pressure. This yields a fiber almost completely insensitive to solarization. The problem is that the hydrogen will diffuse out of the fiber over time, even at room temperature. Once the hydrogen is out-diffused, the fiber returns to the solarization-resistance performance of UVM. Depending on the size of the fiber, the effective life before out-diffusion can be on the order of weeks for small-diameter fibers (100 μm core) to around a year for larger diameters (600 μm core). Environmental temperatures above ambient will increase the rate of diffusion and reduce the effective lifetime of this fiber.

FDP – This type of fiber has been around for almost a decade. An improvement on UVM fiber, FDP fiber has in part replaced UVM as the industry standard. Developed at Polymicro to reduce the solarization sensitivity below that of UVM fiber, FDP improvements were achieved by material and process changes in the design. Since the fiber does not contain dissolved hydrogen, there is not an issue of the performance degrading over time as seen with the out-diffusion effect of UVMI. In FDP fiber, the UV-defect concentrations have been substantially reduced, such that the solarization-degradation resistance properties are optimized.

Enhanced FDP fiber-solarization resistance

In the past year, technological breakthroughs have led to a significant improvement in the solarization-resistance performance of Polymicro deep-UV-optimized FDP fiber. The improved FDP fiber reflects a series of successful efforts to reduce UV-induced defect centers and improve solarization resistance as compared to the existing FDP and UVM fibers.

Although there are no official industry standards for evaluating deep-UV fibers, extensive testing of the improved FDP fiber has yielded the best data available in terms of fiber performance. Results demonstrate that this fiber shows significant reduction in the 214 and 265 nm absorption bands typically associated with solarization effects in fused silica. The improvements were applied to fiber core diameters from 68 to 600 μm. Characterization of the solarization resistance was performed with added attenuation from UV exposure demonstrated to be less than 1 dB per two meters tested for all fibers in the core size range.

Solarization resistance is evaluated using a test known as a "four-hour UV-exposure test." The test uses a 2 m segment of fiber. Light from a high-intensity deuterium lamp is launched into the fiber using a focusing lens to maximize intensity. The focus is aligned to maximize the intensity at 214 nm (generally the most sensitive wavelength for UV solarization). The output of the test sample is monitored using an Ocean Optics (Dunedin, FL) UV spectrometer, and data is collected for 4 hours.

Six important wavelengths are traced throughout the test process (214, 229, 245, 255, 266, and 330 nm). In addition, the entire spectrum is measured and compared at the beginning and end of the test. The rate of degradation of each wavelength decreases as the test progresses, ideally reaching a saturation point before the four-hour end of the test. Quick saturation is a desirable quality in a UV fiber, along with minimum degradation. The level of degradation at saturation is mostly independent of light intensity. Increasing the intensity tends only to change the speed with which the saturation is reached.

As discussed, silica optical fibers are susceptible to UV-induced attenuation caused by damage induced by exposure to UV radiation. Most attenuation occurs in wavelengths less than 275 nm, with the peak damage occurring at 214 nm and 265 nm. The degree of damage varies greatly with the type of fiber. Figure 1 compares the change in transmission at 214 nm during the four-hour UV-exposure test for the four UV fibers discussed previously.Biomedical applications

The optimized FDP fiber showed significantly greater resistance to the formation of defect centers under radiation. The improvement is particularly noticeable in smaller-core-diameter fibers commonly used in minimally invasive biomedical applications requiring UV transmission. The optimized FDP-fiber transmission remains stable under UV radiation over a wider range of input powers than for all other fibers tested. Numerous applications could potentially benefit from this improved performance, ranging from industrial spectroscopy to biomedical applications requiring UV transmission.

Optimized FDP fiber is particularly beneficial to smaller fiber diameters less than or equal to 100 μm diameter, which makes it most useful for in vivo medical applications where small size and high flexibility enable improved and less-traumatic access to remote areas of the body. Highly sensitive Polymicro FDP fiber can be used for photodynamic medical therapies requiring light activation, in addition to a range of dermatological treatments, catheters, and other medical laser applications and diagnostic testing.

Polymicro is a registered manufacturer of medical devices that meet the Food and Drug Administration (FDA) 21 CFR 820 QSR standard (FDA registration ensures the biocompatibility of the fiber materials and sterilization protocols used in the manufacture and delivery of safe medical equipment, including fiber, connectors and subassemblies for biomedical sensing, endoscopic imaging, real-time diagnostic imaging, and thermal ablative treatments using radio-frequency radiation).

ACKNOWLEDGEMENT

This article first appeared in Laser Focus World, 50, 5, 47–50 (2014).

JOHN SHANNON is an engineering manager at Polymicro Technologies, a subsidiary of Molex Incorporated; e-mail: [email protected]; www.molex.com.