Although laser therapy works better than other methods for treating port-wine stain birthmarks, it helps some patients more than others. When Jennifer Kehlet Barton started her graduate work in A.J. Welch's lab at the University of Texas at Austin in the mid-1990s, she joined the lab's effort to understand why.

A port-wine stain is a reddish-purple skin lesion created by swollen blood vessels. Barton says she and Welch suspected that differences in blood-vessel structure might explain the variation in treatment efficacy. And she reasoned that if she could map the blood vessels accurately enough, lasers could be tailored to destroy the vessels–and thereby provide more effective therapy.

At the time, no tool was able to accomplish such accurate mapping of the skin's blood vessels. But optical coherence tomography (OCT) was just getting started–and Barton was thrilled to find that the new approach could indeed map blood vessels in skin with sufficient accuracy. "It was extraordinary," she recalls.

More data per scan

Much as ultrasound uses echoes to create images, OCT uses backscattered light (see "OCT imaging leaps to the next generation," bioopticsworld.com/articles/316650). With that light, OCT can generate two- or three-dimensional images. In 1996, Carl Zeiss, which has its headquarters in Oberkochen, Germany, offered the first commercial OCT device for medical-imaging applications.

This technology's applications in medicine and basic research generate a large market. According to Optical Coherence Tomography–Technology, Markets, and Applications: 2008-2012 (bioopticsworld.com/resourcecenter/OCTreport.html), a market research report, OCT already generates an annual market of $200 million. Moreover, this report indicates that the OCT market is growing at about 34 percent a year, which will push annual OCT revenue to $800 million by 2012.

Advances in OCT technology will fuel this market growth–and work leveraging the technique is increasingly found in academic labs and clinical settings. Also on the increase is work to extract more data per OCT scan.

Eyeing the future

To improve OCT images for ophthalmology, instruments from Carl Zeiss Meditec (Dublin, CA) use oversampling. Scanning the same spot several times reduces background noise and enhances the anatomical image. According to Christine Ritter, director of marketing at Carl Zeiss Meditec, its devices–such as the Cirrus HD-OCT–can scan a location 20 times, and the devices work fast, grabbing data at 27,000 scans per second (see Fig. 1). Consequently, these devices usually gather information before the eye moves or blinks. If any movement does arise during a scan, it can be quickly repeated.

Beyond gathering images quickly, Zeiss OCT instruments for ophthalmology also pull out specific information from the data. For example, the collected data can provide images of the layers within the retina, such as the retinal pigment epithelium. "We want to extract more clinical information from the dense volume of data collected by the Zeiss OCTs," says Ritter. For example, OCT images can be used to evaluate the effect of a drug or to plan eye surgery and check the results. Carl Zeiss Meditec is also investigating an OCT tool that can be used during surgery.

To help clinicians and researchers keep up with the field, Carl Zeiss Meditec built a website called Eye on OCT (oct.zeiss.com). Ritter says, "Eye on OCT is the most comprehensive online resource for ophthalmic articles and educational materials to help doctors gain the most benefit from this complex technology."

Another German company focused on eye imaging with OCT is Heidelberg Engineering (Heidelberg, Germany) which has been developing optical devices for nearly 20 years. The Heidelberg portfolio began to include OCT about five years ago. Now, the company's Spectralis product family combines confocal scanning laser ophthalmoscopy and spectral-domain OCT. According to Kester Nahen, Heidelberg Engineering's vice president of global marketing and business development, "The confocal beam provides an image of the back of the eye, or the fundus, and the OCT provides cross-sectional images of the retina." He adds, "These scanners are coupled with an active eye tracker." So when gathering data on a patient, this technology compensates for eye movements, and future scans can find the same spot on the retina. "This lets a doctor or researcher follow a therapeutic effect very closely and look at the same location every time," Nahen says.

Cancer research beneath the surface

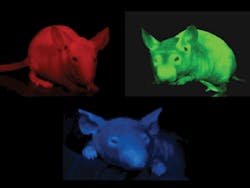

Meanwhile Barton, now professor and head of the department of biomedical engineering at the University of Arizona (Tucson), focuses OCT on other conditions, especially epithelial cancer. For example, she is working with researchers who want to make chemopreventative and chemotherapeutic agents for colon cancer. In this work, OCT can play a fundamental role. "The biggest benefit of OCT," Barton explains, "is that it is nondestructive." So OCT can be used–so far just in mice–to find a colon-cancer tumor and as a follow up after treatment to see if the tumor changes. Instead of sacrificing a mouse to examine a tumor, Barton anesthetizes the mouse and uses OCT. "We can do a colonoscopy to examine a tumor as often as the mouse can tolerate the anesthesia," she adds. "So we can do 3D imaging and watch tumors over time" (see Fig. 2).Making sense of speckle

OCT can even "see" things that researchers cannot. "We can do some image analysis that gathers more information than our eyes do," Barton says. For example, OCT images include speckle, which is often considered noise in an image, but Barton points out that the speckle might tell researchers more about tissues. She says, "OCT images have lots of speckle and information that our brain doesn't process." Image analysis, though, can grab this extra information, which might make this technique an even stronger diagnostic tool.

Over the next few years, OCT will reveal even more ways to study organisms, and this imaging technology will also improve our ability to battle disease.

About the Author

Mike May

Contributing Editor, BioOptics World

Mike May writes about instrumentation design and application for BioOptics World. He earned his Ph.D. in neurobiology and behavior from Cornell University and is a member of Sigma Xi: The Scientific Research Society. He has written two books and scores of articles in the field of biomedicine.