BIOPHOTONICS INSTRUMENTATION/REGULATION: Optical device challenges at FDA

As the U.S. Food and Drug Administration moves forward with plans to update the medical device approval process, emerging technologies continue to present challenges to the agency. In the area of optical devices, the diversity of devices, limited funding and small staffs are stretching the agency’s existing resources. The pressure is likely to increase as a recent FDA medical device forecast suggests that by 2018 photonics devices and advanced imaging systems will be “significant innovation technology areas.”1

To handle the expected increase, the Office of Science and Engineering Laboratories (OSEL) Physics Division plans to add staff. “The need for additional scientists in optics is high,” says Victor Krauthamer, director of OSEL’s physics division. OSEL is responsible for providing scientific data to support FDA’s regulatory decision-making process. Krauthamer notes that FDA would especially like to increase staffing for regulatory research on optical coherence tomography (OCT), but current federal funding issues may delay those plans. To offset limited funding, OSEL is “also leveraging support through university partnerships and other Federal agencies,” he says.

In-house bio-optics testing

Within the Physics Division, the two labs that provide scientific support for emerging biophotonics technologies are the Optical Diagnostics Laboratory led by Joshua Pfefer and the Optical Therapeutics and Medical Nanophotonics Lab led by Ilko Ilev. These labs provide independent research to the Center for Devices and Radiological Health when safety or effectiveness questions arise during the device review process. If issues arise after a device is approved, the labs may perform additional tests to ascertain the problem.

The optics researchers provide data on the basic science behind the devices, create bench test methods for use when comparing devices, and examine issues related to safety. Their work has created standards for image quality and resolution, safe limits for laser radiation, and tools to help companies quantify their results. In the case of OCT, the Optical Diagnostics Lab created phantoms to measure OCT image quality.2 The lab has also developed a Monte Carlo simulation of fiber-optic reflectance spectroscopy devices. The computer model will enable the lab to determine performance parameters for a number of optical diagnostic devices. In addition, the lab’s research has provided insights into areas such as light/tissue interactions, peak power issues, and photobleaching.

Breaking new ground

Pfefer and Ilko say the biggest hurdle they and their colleagues must overcome is the lack of existing test methods for emerging optical devices. “We face major challenges in reviewing optical technologies and devices because we do not always have specific standards of safety and efficacy for optical technologies,” says Ilev. Through their work to develop innovative test methods, the researchers often break new ground.

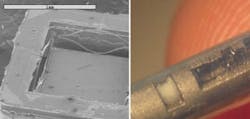

Several years ago, the Office of Device Evaluation needed an independent method to measure several parameters of soft intraocular lenses, new replacement lenses for patients undergoing cataract surgery. The Optical Therapeutics Lab developed a new test method using a fiber-optic confocal laser design to measure the focal length of an intraocular lens. The test method is accurate to less than 1 µm in focal length. Ilko patented the measurement system last year. Among the lab’s other research projects are developing testing methods using OCT and confocal microscopy for biosensing and bioimaging applications.

In addition to occasional patents, much of the work performed by the labs contributes to international standards and the agency’s guidance documents. These “roadmaps” provide the agency’s current thinking on how to approach a given topic. Recently, a lack of standards related to scanning patterns for scanning endoscopic devices led the therapeutics lab to develop data that will be used in a draft guidance document for scanning endoscopic devices, which is scheduled for release later this year. By producing this kind of data, the optics labs add to the clarity and predictability of the review process, “a key to getting a device on the market,” says FDA spokesperson Mary Long.

Knowing what’s around the corner

To stay abreast of new technologies, Pfefer, Ilev, and their colleagues participate in professional meetings through program committee work and attendance and serve as journal editors. “We must see around the corners, be aware of what technology is coming next, and be ready to evaluate the technology when it comes in,” says Pfefer. He notes, however, that the breadth of devices and limited resources requires the labs to prioritize their efforts. “It’s hard to keep a handle on all of the devices, so we must focus on the technologies that are most common, such as optical coherence tomography, spectroscopy, spectral imaging, and fluorescence,” he says.

The optical laboratory staff and reviewers combine their strong knowledge of optical technologies to address the rapidly changing field of biooptics, but as more devices line up for approval, FDA will have to address staffing issues to both protect public health and move good devices to market quickly.

1. http://www.fda.gov/AboutFDA/CentersOffices/CDRH/CDRHReports/ucm234726.htm.

2. A. Agrawal et al., Opt. Lett. 35 (13), 2269–2271 (2010).

3. I. Ilev, “Confocal Fiber-Optic Laser Method for Measuring the Focal Length of Focusing Optics,” U.S. Patent, May 18, 2010.

4. I. Ilev, Eye 21, 818 (2007).

5. K.J. Hoffer et al., J. Cataract Refract. Surg. 35, 1995 (2009).

About the Author