Optical microscopy, spectroscopy duo IDs materials at the nanoscale

An international team of researchers from NanoGUNE (San Sebastian, Spain), Ludwig Maximilian University (LMU; Munich, Germany), and Neaspec GmbH (Martinsried, Germany) have developed an optical instrument that can chemically identify materials at the nanometer scale. The work shows promise for research, development, and quality control in biomedicine and the pharmaceutical industry.

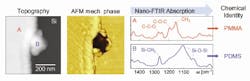

Dubbed nano-FTIR, their instrument combines scattering-type scanning near-field optical microscopy (s-SNOM) and Fourier transform infrared (FTIR) spectroscopy. By illuminating the metalized tip of an atomic force microscope (AFM) with a broadband infrared laser, and analyzing the backscattered light with a specially designed Fourier transform spectrometer, the researchers could demonstrate local infrared spectroscopy with a spatial resolution of less than 20 nm. "Nano-FTIR thus allows for fast and reliable chemical identification of virtually any infrared-active material on the nanometer scale," says Florian Huth, who performed the experiments.

An important aspect of the work is that the nano-FTIR spectra match extremely well with conventional FTIR spectra, while the spatial resolution is increased by more than a factor of 300 compared to conventional infrared spectroscopy.

-----

Follow us on Twitter, 'like' us on Facebook, and join our group on LinkedIn

Subscribe now to BioOptics World magazine; it's free!