AFM-IR enables chemical metrology for medical diagnostics

Joint research conducted by the University of Illinois' Department of Engineering (Champaign, IL) and Anasys Instruments (Santa Barbara, CA) has shown that nanotechnology-based materials identification enables critically needed chemical metrology for nano-manufacturing in medical diagnostics.

While there have been significant breakthroughs in nano-manufacturing, there has been much less progress on the metrology of nanostructures made from multiple integrated materials. Realizing this, the researchers used atomic force microscope-based infrared spectroscopy (AFM-IR) to characterize polymer nanostructures and systems of integrated polymer nanostructures, explains William King, the College of Engineering Bliss Professor in the Department of Mechanical Science and Engineering at the University of Illinois Urbana-Champaign. The researchers were able to chemically analyze polymer lines as small as 100 nm, as well as clearly distinguish different nanopatterned polymers using their infrared absorption spectra as obtained by the AFM-IR technique, he says.

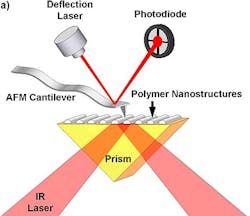

In AFM-IR, a rapidly pulsed infrared (IR) laser is directed on upon a thin sample which absorbs the IR light and undergoes rapid thermomechanical expansion. An AFM tip in contact with the polymer nanostructure resonates in response to the expansion, and this resonance is measured by the AFM.

"While nanotechnologists have long been interested in the manufacturing of integrated nanostructures, they have been limited by the lack of tools that can identify material composition at the nanometer scale," says Craig Prater, co-author on the study and CTO of Anasys Instruments. "The AFM-IR technique offers the unique capability to simultaneously map the morphology and perform chemical analysis at the nanoscale."

For more information on their work, which has been published in the journal ACS Nano, please visit http://pubs.acs.org/doi/abs/10.1021/nn302620f.