Electron microscopes provide incredible resolution, but they’re of little use to life scientists because they cannot image living tissue. Light microscopes do enable observation of live tissues, but the diffraction barrier limits their resolution to about 200 nanometers.

What’s a biologist to do? Seek “super-resolution.” The term applies to any technique that bypasses the diffraction limit to takes light microscopy to a higher resolution.

“Super-resolution using conventional lenses and focused light has the potential to transform many areas in the life sciences,” says Stefan Hell, director at the Max Plank Institute for Biophysical Chemistry (Göttingen, Germany). “Twenty years ago, hardly anyone thought this would even be possible.” Now, though, scientists use a range of approaches to bypass the diffraction barrier. “All do that with certain kinds of tricks to overcome that physical limit,” says Bernhard Götze, product manager for Carl Zeiss (Jena, Germany).

Tested tricks

The first “trick” that broke the diffraction barrier was stimulated emission depletion (STED) microscopy. This technique sharpens the focus on a fluorescent point by inhibiting fluorescence on the edges. Hell says, “STED has developed tremendously during the past years, especially since the lasers that you need have become simpler, cheaper, and more compact.” In fact, this once do-it-yourself-only technology is now available commercially in the TCS STED microscope from Leica (Wetzler, Germany). According to Hell, “This method provides a resolution of 30 to 40 nm in 3-D.” The TCS, though, only provides about 90 nanometers of lateral resolution.

This form of microscopy also works fast; it’s capable of video-rate imaging. In the February 26, 2009, Nature, for example, Hell and his colleagues report on using STED to study the dynamics of single lipid molecules in the plasma membrane of living cells. “We quantified the dynamics,” Hell says.

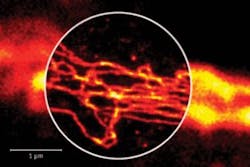

Super-resolution can also come from photoactivated localization microscopy (PALM). With this technique, a scientist attaches a photoactive label to a molecule to be imaged. Then, violet light turns on some of those labels, and a microscope grabs an image. Then, those labels bleach out and another flash of light turns on others. After doing this thousands of times, a scientist gets an image of all of the labels with a resolution of about 20 nm or better.

This technique, though, works best when looking close to a specimen’s surface. If a scientist tries to look too deep, too many labels turn on simultaneously–making a noisy image. For better control, Charles Shank of the Howard Hughes Medical Institute (Ashburn, Virginia) and his colleagues “sculpt” the illuminating light beam. “We create a hockey puck of light with a diameter and depth that you could not achieve with just a lens,” Shank says. Using group velocity dispersion–essentially using wavelength to control the overall velocity of a group of waves and, thereby, its shape–Shank can excite a region of a sample that is about 1 µm deep and 15 to 20 µm across. “We can move this through the sample and then perform PALM,” Shank explains. In this way, Shank creates a three-dimensional image.

Not so negative

Super-resolution comes from more than fluorescence. More than 40 years ago, Victor Veselago, a Russian physicist, suggested the possibility of a lens with a negative refractive index. Simply put, this means that light that hits an intersection between a material with a positive refractive index and a negative one will bend in the opposite direction to what you would expect from ordinary refraction. The trouble was no one could make a material with a negative refractive index. Metamaterials changed that. These composites consist of polymers and metals, such as silver or gold. Yet, it still takes more than a metamaterial to get Veselago’s lens.

To get super-resolution with such a superlens, you also need a surface-plasmon polariton (SPP), which will run along the boundary of the metal and polymer in a metamaterial. There’s one more thing: you also need nanoscale grooves, carved precisely on the surface of the metamaterial. “You’re making something like a diffraction grating on the material’s surface,” explains Christopher Davis, professor of electrical and computer engineering at the University of Maryland, College Park.

If you put something small, like a cell or virus, on a metamaterial and shine light on it, the light makes an SPP of the same wavelength as the illuminating light, but the SPP slows down as it moves through the metamaterial–sort of compressing the SPP, which shortens its wavelength. “When the surface plasmon reaches where the object is sitting,” explains Davis, “it disturbs the plasmon, making it scatter some light.” Then, the grooves in the surface magnify the image of the scattered light, so that a conventional light microscope “sees” it. For example, a superlens can resolve things as small as 30 nm.“Our microscope lets you see small objects,” says Davis, “but with some distortion and artifacts.” The key, he says, is making the right grooves in the surface to turn the SPP into a high-quality image. Davis hopes that biologists can eventually buy slides–made of metamaterial and pre-etched with nanostructures–that provide a superlens for ordinary microscopes.

To gain resolution, scientists can also use a grating to turn high-frequency information into a lower-frequency Moiré pattern, which an ordinary microscope can pick up. Then, computation returns the high-frequency–higher resolution–features to the image. This is the essence of structured illumination microscopy (SIM). “This provides twice the resolution of confocal,” says Ingo Kleppe, applications specialist for advanced development at Carl Zeiss. Zeiss plans to release PALM and SIM scopes later this year.Another advantage of SIM is that it works on standard specimens. “We do not need to change stain protocols or invent new fluorescent proteins,” says Götze. STED and PALM, by contrast, require very specific sample preparations.

However a researcher uses light microscopy to overcome the diffraction barrier, it is a worthwhile journey. “Almost everything inside a cell that is of interest for biomedical applications is smaller than this diffraction barrier,” says Götze.

About the Author

Mike May

Contributing Editor, BioOptics World

Mike May writes about instrumentation design and application for BioOptics World. He earned his Ph.D. in neurobiology and behavior from Cornell University and is a member of Sigma Xi: The Scientific Research Society. He has written two books and scores of articles in the field of biomedicine.