High performance with fluorescence optical filters

Hard-coated filters offer many improvements over legacy “soft”-coated filters. That’s why there’s a shift under way toward the newer, high-density filters. But implementing them requires some knowledge to extract best possible performance.

By Ben Standish

Editor’s note: For more on the current state of optical filtering, see this issue’s installment of Inside Instrumentation, p. 38.

Systems that use fluorescence—including microarray scanners, flow cytometers, fluorescence imaging systems, and fluorescence microscopes—are shifting from legacy “soft”-coated filters to higher-density “hard”-coated filters. Hard-coated filters offer a wide range of improvements. In real-time polymerase chain reaction (PCR), the best optical-filter technology enables earlier detection of disease and reduced costs of providing targeted screening.

Manufacturing hard-coated filters, however, is a challenge. And implementing them can require updates to optical- system design for best performance.

Hard vs. soft

Historically, most volume-manufactured instruments and equipment that use visible or near-visible wavelengths have used “soft” filter technology. Since the mid 20th century these interference-based filters have been made using alternating, evaporated layers of high- and low-optical-index materials. Thickness, order, and number layers have been arranged to produce the desired effect on the transmitted light. These are most often “bandpass” filters that transmit a designated range of wavelengths and block adjacent wavelengths. “Edge” filters, another common type, transmit wavelengths either above (long pass) or below (short pass) a designated point. A dichroic filter is generally an edge filter optimized for a 45° incident angle.

“Soft” filters are of low density and not durable. They must be sealed to ward off the ill effects of moisture on performance and lifetime, usually by laminating the coated surfaces between at least two glass substrates. The number of layers that can be deposited by the soft evaporative method is limited, so creative methods help improve results. To aid optical blocking performance over the wide emission range of the instrument light source (often a xenon or halogen bulb), colored glass is used to absorb, rather than reflect, some of the bulb’s spectrum. While this is an inexpensive way to expand the blocked wavelength range, it also significantly reduces transmission levels of the desired wavelengths. Improper orientation of soft filters can reduce filter lifetime because of the thermal response of absorbing materials in soft filter fabrication. Further, induced transmission design of soft coated filters requires thin silver layers that corrode over time even in a lab’s ambient environment.

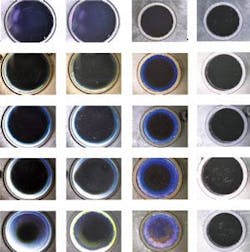

“Hard” filter technology offers major gains in filter performance and lifetime. Hard-coating technologies use one of several methods to bombard layers with ions to achieve high-density, robust, hard-oxide films. The deposition of metal oxides can be tightly controlled, typically by in-process optical-transmission monitoring, for high- and low-index layer thickness. They do not need to be sealed, nor do they require special handling. In damp, heat-accelerated life tests performed by Bookham (see Fig. 1), soft coating filters usually begin to fail in the first few cycles with visible destruction of the filter aperture beginning from the edge. By contrast, hard-coated filters survive identical tests with no visible or measurable impact.

A further hard-filter advantage is that a greater number of layers can be deposited. This allows simpler filter designs (without colored glass) and greater transmission, enabling performance over the wavelength ranges required by fluorescence applications. The result is an optical filter that is extremely durable, has high passband transmission, and offers deep blocking over a wide range. Thus, fluorescence excitation intensity can be very high while fluorescence emissions more than six orders of magnitude less are detectable at adjacent wavelengths. This is generally achieved with one, or sometimes two, glass substrates and no absorbing glass, epoxy, or laminates in the optical path.

Realizing the gains

The performance advantages of the newer hard-coating technologies are relatively easy to quantify, in transmission levels approaching 100%. Higher transmission leads to brighter images in fluorescence microscopy, which is evident in brilliant photos of cell and tissue fluorescence. High-transmission filters used for fluorescence imaging via multiwell plates or microarrays for research and diagnostics enable greater measurement sensitivity and higher throughput. Processing more tests faster improves instrument utilization and lowers costs.

Higher-performance filters reveal optical-system shortcomings in much the same way that high-definition television reveals imperfections on the complexions of TV news anchors. While hard filters can often function as drop-in replacements for lower-transmission soft filters, optical systems can—and sometimes must—be optimized to benefit from the improved performance.

The high-transmission advantage, enabled by the elimination of colored glass, can require new considerations in optical-system and filter design, especially in terms of controlling stray light. Colored glass acts as an effective, if blunt, method for limiting the range of transmitted light—but it does so for all incident angles. When relying solely on optical-filter layer design to determine filter performance, the incident angle and light-beam cone angle must be considered. Perfectly normal and collimated beams will “blue-shift” to shorter wavelengths at angle. While this shifting holds true for both soft- and hard-coated filters in the filter’s bandpass region, soft coatings’ colored glass absorbs high-angle light at the blocked wavelengths.

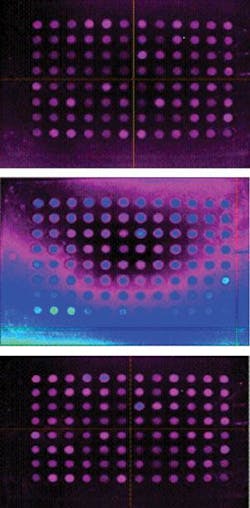

Accordingly, successful implementation of hard filters needs to minimize stray light in the optics system. This ensures that only the specified angles of light pass through the filters, thus reducing background noise and increasing system sensitivity (see Fig. 2). Because high-sensitivity instruments record fluorescence beyond the optical-density six measurement levels (OD6, or 0.0001%) relative to excitation light, it takes very little stray light to negatively impact results.

Meeting spec

Measurement of high-performance optical filters also presents a practical challenge, especially for volume OEM applications that require consistent performance at the cutting edge of today’s capabilities. The best spectrophotometers available today involve a trade between low noise and high resolution given the wide filter spectrum, often as broad as 350 to 1200 nm. OD6 blocking levels are the lowest measurements possible with spectrophotometers that can be used in a production environment. To prove the feasibility of optics systems that detect fluorescence below this level, often a detailed study of theoretical filter designs is done with considerations of the instrument optics design. High-performance applications, especially ones requiring FDA approval, must have documented test results for 100% of shipped filters, all to detailed specifications. Scientists and engineers require exacting tolerances for where the bandpass and blocking region boundaries will be. Merely classifying a filter set for a fluorescing dye with references to typical filter performance leaves too much variation in assays optimized for the best possible sensitivity.

The nature of optical-filter production makes many suppliers unable to offer OEM volumes to precision parameter tolerances. Suppliers strive to establish hard-coating methods that combine deposition speed and broad-area wavelength uniformity—and these key factors determine a supplier’s ability to meet tight specifications and keep costs low.

Given the limitation of off-the-shelf hard-coating deposition chambers available, industry leaders develop proprietary methods and machines to achieve desired results for their target applications. An example of this is Bookham’s Advanced Energetic Deposition (AED), a process that enables the company to produce high-accuracy filters in wavelengths from the visible to the near-infrared. AED was developed for high-performance telecommunications applications, and the same machines and methods have generated tight-tolerance 25 mm fluorescence filters for OEM applications. The process produces thousands of hard-coated filter sets per year made to custom specifications with tolerances as tight as ±1 nm.

It is exciting and rewarding to see the benefits of high technology reach beyond theory and one-off samples into real- world applications and volume. The time is now for the implementation of hard-coating filters. The benefits are many, manufacturing methods are mature, and there exists a means to fulfill tight specifications in volumes that OEM applications require.

Ben Standish is product line manager, Bookham Thin Films Division, 3640 Westwind Blvd Santa Rosa, CA 95403. Contact him at [email protected]; www.bookham.com.