Novel light engine challenges lasers, lamps, and LEDs in life sciences

Lumencor (Beaverton, OR), a year-old company focused on the development of novel light engines, is targeting life-science instrumentation with its initial products and is gearing up to move from prototype phase to volume manufacturing by the fourth quarter of 2008. According to Claudia Jaffe, vice president of business development, the life-science industry is undergoing fundamental changes, with researchers placing greater demand on their analytical equipment for increasingly sensitive and specific analyses, and high-intensity, low-cost light sources are essential to the design of these new instruments.

Many life-science instruments demand a stable source of light. Lasers, arc and tungsten lamps, and LEDs are the most common light sources currently used in these instruments. But each has limitations that can affect the design and performance of the instrumentation, according to Jaffe. Too few colors are available from lasers, and they are typically expensive. Lamps are hot, large, and unstable. LEDs are limited to certain colors with sufficient power. Most important, Jaffe notes, none of these sources meets the need for the wide spectral range of outputs, higher power, color stability, and durability needed for the expanding range of diagnostic applications and biomarkers.

This is where Lumencor’s patented light-engine technology comes in. Lumencor’s products are complete light engines with up to four color outputs. These light engines provide high-power, spectrally pure, stable, and inexpensive light across a broad spectrum. They can be modulated in intensity and wavelength with no external mechanical components, making them a “smart” light engine. They are designed to directly replace the entire configuration of light-management components with a single, simple unit.

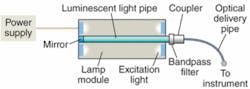

Each light-engine subsystem consists of a lamp module and delivery optics (see figure.). Light is generated by a luminescent light pipe that is driven by an e-beam, LEDs, or ultraviolet lamps. The pipe, which can consist of any of a variety of luminescent materials—such as rare-earth-doped glass, organic-doped plastic, or single-crystal fiber) is tailed to emit light in the UV through the IR. Any unwanted light is removed by a simple bandpass filter. The light output from the pipe is fed into an optical delivery pipe and into the instrument. The fast luminescence decay results in rapid switching with no appreciable warm-up time.

Five wavelengths

Lumencor has identified five wavelengths based on the most common fluorescent dyes used today and the common sets of dyes most often used in sets of two, three, or four. These dyes and dye sets are used in microscopy, whole cell analysis, DNA sequencing, PCR, and other instrument applications throughout the life sciences. Each of the colors produced by Lumencor light engines requires a unique combination of light pipe and excitation source.

Each instrument application requires one of several approaches to coupling light from the delivery pipe into sample volumes.

“Light pipes have been around for a while, but the application of light pipes is new, and that is what our patent covers,” Jaffe says. “In terms of the technology, what is unique is that all the modulation is inherent to the light engine. You can switch between the four colors (405, 488, 561, and 633 nm) and also switch the intensity, up to 1 megahertz. This capability gives the user a range of intensities and colors that can be selected and modulated freely without any external mechanics. Because we control the chemistry (dopant) in the light pipes, we can control the output from the UV to the visible and into the IR.”

Lumencor is targeting five market sectors in the life sciences: bioanalytical instruments, lab-on-a-chip technologies, optical sensors, medical devices based on luminescence, and diagnostic analyzers. Its first light engine products are designed for fluorescence microscopy; future engines will be geared toward other microscopy and spectroscopy techniques, clinical chemistry and immunoassay analyzers, flow cytology, microarray readers, and sequencing tools. Earlier this year the company was awarded a $102,425 Small Business Innovation Research grant from the National Institutes of Health to support the development of its technology and products. –KK