Metasurface Optics: Broadband achromatic metalens focuses all polarizations

Optical metasurface lenses, which are made of subwavelength arrays of nanostructures of varying geometries and thus can form a true flat lens, are looking more and more like they could be practical replacements for refractive lens elements, or even entire refractive lens systems, for some applications. This type of metalens design has had some barriers to overcome, though: one is the difficulty of moving beyond narrowband performance, and another is the fact that designing a metalens to focus both polarizations (and thus unpolarized light) is difficult. Metalenses for general use would need to have both of these characteristics.

Researchers have believed that symmetric nanostructures such as circular pillars were essential building blocks to develop metalenses that are not sensitive to polarization. Now, researchers from the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) at Harvard University (Cambridge, MA) have developed a polarization-insensitive metalens consisting of nonsymmetric nanofins that can achromatically focus light across the visible spectrum without aberrations.1 This flat lens could be used for everything from virtual or augmented reality headsets to microscopy, lithography, sensors, and displays.

“By making this lens polarization-insensitive, we have doubled the efficiency of the metalens from previous iterations,” says Wei Ting Chen, a research associate at SEAS. “This is the first paper that demonstrates both achromatic and polarization-insensitive focusing in the visible spectrum.” The research was led by Federico Capasso, whose group at SEAS has come up with many previous advances in metalenses, including a meta-optical system for handheld spectrometers, a wide-angle, high-efficiency polychromatic metalens, and a metasurface polarimeter on a chip.

In previous research, Capasso, Chen, and their team demonstrated that arrays of titanium dioxide nanofins could equally focus wavelengths of light and eliminate chromatic aberration, but those lenses could only focus a circularly polarized light. “This meant we were essentially discarding half of the incident light which does not possess the right polarization,” says Alexander Zhu, a graduate student at SEAS.

Diffraction-limited from 460 to 700 nm

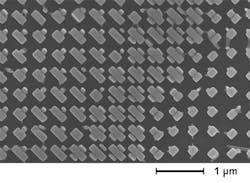

In this latest design, the researchers changed the layout of the nanofins, positioning each pillar so that it is either parallel or perpendicular to its neighbor. “This new design gives us a lot of freedom to tune the geometrical parameters of the metalens, which allows us to better achieve achromatic focusing across the entire visible range,” Chen says.

The experimental lens, which has a diameter of 26.4 µm and a numerical aperture (NA) of 0.2, has diffraction-limited imaging quality across the visible wavelength band of 460 to 700 nm (which encompasses blue, red, green, and the colors in between).

The metalens design was created using a finite-difference time-domain (FDTD) solver to obtain each element’s phase, group delay, and group delay dispersion, and optimized via a “particle swarm” method that found optimal shifts for phase, group delay, and group delay dispersion (see figure). The lens itself was fabricated from a film of titanium dioxide (TiO2) using electron-beam lithography. The anisotropic nanofin design is what allowed the researchers to accurately and simultaneously optimize the phase and its higher-order derivatives (group delay and group delay dispersion) with respect to frequency. The result is a device with a diffraction efficiency of 92% at 530 nm and a focusing efficiency that varies by at most 4% over various polarizations.

The 26.4 µm diameter of the lens is limited by the achievable group delay in nanostructure elements—about 5 fs in the 600-nm-tall nanofins used in the lens. To create a larger-diameter lens will require either taller nanofins, hyperbolic metamaterials, or a hybrid diffractive-refractive lens design. “Next, we aim to maximize efficiency and make much larger-size achromatic metalenses to bring them into everyday life for a wide range of applications,” Capasso says.

REFERENCE

1. W. T. Chen et al., Nat. Commun. (2019); https://doi.org/10.1038/s41467-019-08305-y.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.