Non-laser Light Sources: High-luminance LEDs target emerging automotive lighting applications

JY BHARDWAJ and OLEG SHCHEKIN

Laser diodes were first adopted in lighting as spot lighting range extenders in automotive, military, and surveillance applications. But as digital lighting becomes more adaptive, there is increasing need for applications that not only convey concentrated illumination, but also transmit information. As a result, there is a renewed focus on increasing the luminance of low-cost light-emitting diode (LED) technology for existing and emerging applications.

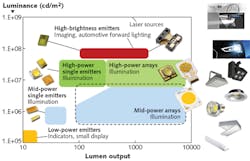

Several years ago, the brightest phosphor-converted LED (pcLED) sources in production were up to a hundred of million nits (MNits for a million nits or mega nits, where a nit = 1 cd/m2). Now, deployed commercial performance in automotive headlighting is above 100 MNits (see Fig. 1) and the newest sources entering the market are approaching 200 MNits.

Applications driving increasing luminance are automotive high-beam range extension and headlight foreground projection. For high-beam range extension (HBRE), >500 MNits is required while Foreground Projection (FGP) overlay requires 100–200 MNits. Even though pcLEDs can achieve these luminance requirements, there is a need for high-volume products that offer lower cost, higher efficiency, and longer lifetime at automotive operational temperature. Free from the safety hazards of high-power laser diodes, high-luminance LEDs have the potential to achieve these goals through material and packaging advances.

Luminance targets by application

Production pcLEDs currently span an illuminance range up to 200 mega nits, which fully meets the needs of the biggest market segments, including general illumination, display backlighting, and automotive interior and exterior front, signal, and rear lighting.

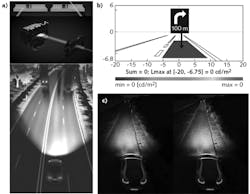

It was LEDs that enabled the digitization of automotive headlights, resulting in entirely new functionalities such as advanced driving beam (ADB). In ADB, pixelated arrays of LEDs with a few mega nits of luminance are imaged onto the road and based on feedback from sensors (detecting vehicles, signs, pedestrians, and other objects on or near the road), individual pixels can be turned off or dimmed to create a range of functions, including reduced glare for other road users, ability to highlight pedestrians, signs, and obstacles, and dynamic steering of the beam as the car approaches bends in the road (see Fig. 2).To expand driving safety, pcLEDs can also provide FGP overlay information on top of the roadway, such as lane markings or warnings. Within FGP, there are two distinct applications: 1) direct LED imaging that requires 100 MNits, and 2) LED illumination of MEMS micromirror arrays such as the Texas Instruments digital micromirror device (TI DMD) with around 1 million pixels—requiring closer to 200 MNits.1

The HBRE application focuses more on high-speed freeway driving, where on straight roads, the vehicle can light up the path ahead on its side of the highway only up to the legal limit of 600 m. This requires >500 MNits to generate a narrow spot beam.

As a performance target, we need LEDs to achieve 100, 200, and then 500 MNits to meet the full range of needs, which is up to 1750 lm/die for a light-emitting area (LEA) of 1 mm2 (assuming a Lambertian radiation pattern in the far field and uniform luminance across the emitting surface in the near field). If we take the baseline performance of a best-in-class high-power LED as 350 lm at 1 A/mm2, that means we need a factor-of-five increase in lumens for the LEA.

The luminance challenge

Essentially, increasing luminance requires increasing electrical current and, hence, power into the LED. As the current density increases in LEDs above a threshold value of approximately 100 mA/mm2, non-radiative recombination increases with increasing current density, resulting in continuous lowering of efficiency known as the “droop” phenomenon.2 The net lumens out still increase, albeit at a lower rate.

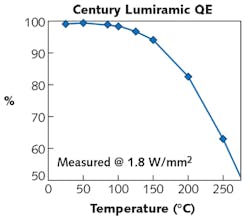

A typical off-the-shelf blue “pump” LED has an efficiency optimized for an operating range of 0.35 to 1.0 A (see Fig. 3). To achieve a 5X increase in output flux, an 8X increase in current density is needed—from 1 to 8 A/mm2. This impacts the forward voltage (Vf) with an increase up to 5 V, with wall-plug efficiency (WPE) decreasing to just above 20%. But can LEDs actually be driven this hard? To find out, designers need to first consider the phosphor material that converts the blue pump flux to white.Phosphor considerations

Phosphors exhibit photothermal quenching (PTQ), wherein the emission decreases as the surrounding temperature is increased by driving the LED to higher power densities.3 Ceramic phosphors are best suited for high drive currents as the reduced activator concentration and high thermal conductivity of ceramic significantly reduce PTQ in these materials.Driving an LED at 8 A/mm2 creates a few major die challenges, including electromigration and current crowding. Electromigration, wherein high current density causes atom movement in the LED active region that creates dislocations and point defects that reduce light output by creating heat, oftentimes requires a complete redesign of the metal and dielectric stack. And current crowding at the LED contacts is manifested as a very high local current density that creates local regions with high droop, again requiring a redesign of the contacts to improve current spreading.5

Lumileds’ redesigned LED features improved current spreading, electromigration resistance, and reduced droop by 10% while maintaining long-term reliability and stability above 3 A/mm2 continuous operation. This takes the company close to 1000 lm/mm2 or >200 MNits. But to compete against phosphor-converted lasers, we need to lower cost and improve efficiency.

Current high-power blue edge-emitting lasers are approximately 30% efficient—and this is viewed as a relatively inefficient source as it places a high demand on thermal management, adding further costs. Lumileds’ 200-MNit LEDs operate at 3 A/mm2 using epitaxial processes specifically optimized for this current density, resulting in >40% efficiency and already satisfying a number of high-luminance applications.

New materials and package designs

Lumileds continues to explore development options to achieve 500 MNits and believes that LEDs should not only be able to handle extreme power loads, but must also do so efficiently. In addition to incremental improvements in droop reduction using new die and epitaxy designs plus shifting to shorter pump wavelengths, the company is investigating additional options such as new materials and packaging methods.

Transitioning to semi- and non-polar gallium nitride (GaN) reduces polarization effects that create the fundamental electron-hole wave function overlap in the quantum wells at very high current densities in c-plane-oriented GaN.6 And transitioning to radically new device architectures incorporating tunnel junctions allows LEDs to be stacked, almost doubling the luminance for the same current density.7 Our target is to achieve >40% efficiency at 8 A/mm2 with our current LED architectures. By using new approaches, we forecast that LEDs will achieve 500 MNits by 2021.

REFERENCES

1. V. R. Bhakta and B. Ballard, “High resolution adaptive headlight using Texas Instruments DLP [copyright] technology,” 2015 International Symposium on Automotive Lighting (ISAL) Proceedings, 483-494, Darmstadt, Germany (Sep. 2015).

2. V. Fiorentini and F. Bernardini, Phys. Rev. B, 60, 12, 8849 (1999).

3. O. B. Shchekin et al., Physica Status Solidi RRL, 10, 4, 310 (2016).

4. R. Mueller-Mach et al., Physica Status Solidi RRL, 3, 7–8, 215 (2009).

5. J. Bhardwaj et al., Physica Status Solidi A, 214, 8 (2017).

6. B. Leung et al., Appl. Phys. Lett., 104, 26, 262105 (2014).

7. S. Krishnamoorthy, F. Akyol, and S. Rajan, Appl. Phys. Lett., 105, 14, 141104 (2014).

Jy Bhardwaj is chief technical officer and Oleg Shchekin is vice president of LED architecture, both at Lumileds, San Jose, CA; e-mail: [email protected]; www.lumileds.com.