Novel Light Beams: Curved 'photonic hook' easier to produce than Airy beams

Created using a laser and a spatial light modulator (SLM), Airy beams do not obey the otherwise linear path of light, but are instead self-healing, free-acceleration beams that bend in a parabolic arc without diffraction. They have important implications for moving particles in microfluidic applications and guiding surface plasmon polaritons along metal-dielectric interfaces, increasing terahertz wave intensity, and even for guiding electric arcs such as lightning.

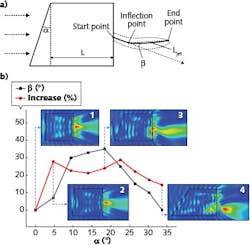

A simpler way to produce a curved beam of light, however, has been developed by researchers at Tomsk Polytechnic and Tomsk State Universities (both in Tomsk, Russia), Bangor University (Bangor, North Wales), and ITMO University (St. Petersburg, Russia) by focusing a plane wave into a simple wedge prism and cuboid structure (see figure).1 The degree of curvature of this light beam—dubbed a "photonic hook" by the researchers—is influenced by the size of the cuboid and angle of the chosen prism.

Breaking the diffraction limit

Using commercial finite integral technique (FIT) software from CST Microwave Studio (Darmstadt, Germany and Framingham, MA), the dielectric prism/cuboid structure was modeled to optimize the hooked beam when using fused silica (refractive index = 1.46) wedge prisms with different inclined prism angles α and cuboids with equal length, width, and height L (normalized to 1 λ, 2.5 λ, and so on up to 4.5 λ) for a λ = 532 nm plane-wave source. Transmission experiments also included a comparison with a plain cuboid structure.

Without the wedge prism, the symmetric cuboid-only structure produced an electric-field enhancement or photonic jet, as expected, along the transmission axis. However, the addition of the wedge creates the asymmetric structure that curves the light upon exiting the cuboid to a degree dependent on the wedge angle α. For an optimized α = 18.43°, for example, the largest photonic hook or curved-light structure is formed with a β value of 35°, where β is defined as the degree of curvature based on an angle formed by a curve fitted from the start/inflection/end point of the resultant photonic hook.

As the L value increases from 1 λ up to 4.5 λ, the photonic hook power distribution is physically lengthened, with the longest and best-defined hook obtained for L = 3 λ. The full-width half-maximum (FWHM) of the optimum photonic hook is shorter than that for a linear photonic jet produced by a plain cuboid structure—furthermore, the photonic hook breaks the simplified diffraction limit (0.5 λ criterion).

Wavefront analysis of the prism/cuboid structure reveals that the unequal phase of the transmitted plane wave (perpendicular to the y or transmission axis) results in the irregularly concave deformation of the wavefront inside the structure that then leads to creation of the photonic hook, which can be more easily visualized as a light beam with astigmatism on the macro scale.

"The concept of a curved photonic nanojet named a 'photonic hook' as an optical trap to move particles behind a barrier was initially introduced by myself and Oleg V. Minin," says Tomsk Polytechnic professor Igor V. Minin.2 "As is well known, curved Airy beams require massive supporting systems including SLMs and microscopes that make them incompatible, for example, with microfluidic devices. On the contrary, the photonic hook is simple and compact for microscale implementation and on-chip devices. Other effects of the photonic hook are now under investigation, including as scalpel tips for ultraprecise surgery, for cloaking systems, as light-sheet illumination imagers, and as vortex photonic jets."3

REFERENCES

1. L. Yue et al., Opt. Lett. (accepted 2018); http://arxiv.org/abs/1712.10075.

2. I. V. Minin and O. V. Minin, Patent of Russia 161207, "Optical trap in the form of photonic hook" (2016).

3. O. V. Minin et al., "Aided photonic jet scalpel tips for potential use in ultraprecise laser surgery," 2015 International Conference on Biomedical Engineering and Computational Technologies (SIBIRCON), 18–21 (Oct. 28-30, 2015).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.