Nanotechnology-based VIS-SWIR detectors challenge limits of InGaAs designs

Recognizing that the high cost of indium gallium arsenide (InGaAs)-based photodetectors in the visible (VIS) through shortwave-infrared (SWIR) region is limiting certain emerging applications, research groups and sensor companies are developing novel detector architectures and materials to address this dilemma. Emberion Oy (Espoo, Finland) is among these pioneers, introducing a 1 × 512 array sensor at SPIE Photonics West 2018 on the heels of its single-pixel sensor that uses nanotechnology to lower cost and overcome volume and performance limitations of InGaAs devices.

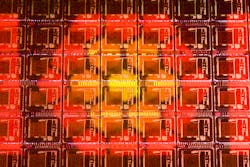

Built using graphene charge transducers combined with a nanocrystal light absorber on a complementary metal-oxide semiconductor (CMOS) platform, Emberion's single-pixel sensor has a 1 mm2 detection area, operates over a 400–1600 nm wavelength range with noise-equivalent irradiance of <10-4 W/m2 at 1600 nm, has a 100 Hz sampling rate and 120 dB full dynamic range, and has a detection stability of <5% per year for applications in gas sensing and incorporation into power meters. Although thermoelectric cooling is available, cooling below room temperature is not required to achieve the stated specifications.

In addition to the now commercially available 1 × 512 array that targets VIS-SWIR spectroscopy applications, Emberion will be launching a focal plane array (FPA) sensor in early 2019 to suit night vision and machine vision. Preliminary FPA specifications include a 400–1800 nm wavelength range, 20 μm square pixels with 20 μm pixel pitch in a 640 × 512 (VGA) format, 100 frames/s maximum frame rate, and 80 dB full dynamic range. This imaging sensor module can be readily incorporated into a camera core. Reference: http://pubs.acs.org/doi/abs/10.1021/acsnano.7b00760.

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.