Diffractive Optics: How ultrashort laser pulses influence beam-shaping optics

ISRAEL GROSSINGER, SHLOMIT KATZ, NATAN KAPLAN, and ALEX SKLIAR

As ultrashort-pulse (USP) lasers—also called ultrafast lasers—become more common in industrial use, beam-shaping applications using diffractive optical elements (DOEs) become more challenging, especially as nanosecond pulsed USP lasers are replaced by even-faster femtosecond devices.

Using the physical-optics simulation tool VirtualLab developed by LightTrans International (Jena, Germany; www.lighttrans.com), which can accommodate most DOE families (including beamsplitters and beam shapers), our team at Holo/Or has studied the influence of USP lasers on DOE functionality and found that while effects on most beam-shaper DOEs are negligible, high-angle beamsplitters such as grating-based DOEs can see significant and undesirable chromatic effects.

DOE basics

For many applications, DOEs can be used to generate unique optical functions that are not possible using conventional reflective or refractive optical elements, offering flexibility in terms of system configurations. Some DOE advantages include small footprint, multiple functionality on a single element, high angle accuracy, low thickness, and less temporal dispersion compared to refractive solutions.

The operational principle is a quite straightforward: for a collimated input beam, the output beams exit the DOE with a pre-designed separation angle and intensity. With beam shapers, the laser beam is focused into an engineered spot of the designed size and shape. Common applications for DOEs include medical systems, metrology, and scientific/research applications—in particular, the laser beam-shaping and homogenization techniques afforded by DOEs are essential for materials processing.1

While versatile and robust, DOEs are highly chromatic in that their functionality depends strongly on the wavelength of light.2 This raises concerns when working with USP lasers, which may have unusual spectral characteristics because of their short pulse durations. The wide spectral range of the USP can impact beam shaping using DOEs since the operation wavelength is different than the nominal one for which the DOE is designed. This makes it necessary to predict how the shaped spot would look while using a wavelength range instead of a single wavelength.

According to Fourier theory, the shorter the pulse duration in the time domain, the larger is the spectral width in the frequency domain. This causes USP lasers to exhibit temporal chromatic-dispersion effects. For an 800 nm centered Gaussian pulse, the typical pulse broadening will be Δλ = 1 nm for a 1000 fs pulse and Δλ = 10 nm for a 100 fs pulse.

Beam shaping and splitting

There are two main families of DOE products: beamsplitters and beam shapers. Beamsplitters are DOEs used to split a single laser beam into several beams with different power levels and angles of propagation. The beamsplitter can generate either a one-dimensional beam array (1 × N) or a two-dimensional beam matrix (M × N), depending on the diffractive pattern on the element surface. Optical beamsplitters are used with monochromatic light and designed for a specific wavelength and angle of separation between output beams.

Optical beam shapers are DOEs used to transform a near-Gaussian incident laser beam into a uniform-intensity spot of either a round, rectangular, square, line, or other shape with sharp edges in a specific work plane. The uniform intensity distribution achieved by the beam shaper enables homogeneous treatment of the surface, preventing over- or under-exposure on the workpiece. In addition, the spot is characterized by a sharp transition region that creates a clear border between the treated and untreated area. Beam shapers include homogenizers, top hats, vortex lenses (spiral phase plates), and diffractive axicons.

Beamsplitters and beam shapers can be used with multimode (MM) or single-mode (SM) input beams, and can be operated with high-power laser systems because of the high damage threshold of the materials from which they are fabricated, including fused silica, zinc selenide (ZnSe), and sapphire, for example.

USP effects on beam shaping

When transmitting USP laser light with extremely short pulses of a few femtoseconds through a beamsplitter DOE with a periodic, grating-like structure, many different phenomena may be observed, including elliptical rather than round spot shapes, increased spot size, or significant power in the zero order.

A beamsplitter DOE is designed and manufactured for a nominal wavelength λ1. Its phase is replicated in space, thus forming a periodic grating structure. When a different wavelength λ2 is used, the angle of diffraction changes according to the grating equation.

For small diffraction angles θ (<12°), the relation between the diffraction angle and corresponding wavelength is defined as:

Δd = ƒ · (θλ1 - θλ2) = ƒ · θλ1· (1 - λ1 / λ2)

Here, Δd is the deviation of the spot centers for λ1 and λ2, ƒ is the focal length of the lens in use, and θλi is the diffraction angle of the wavelength λi. Per the equation, each wavelength will have a different diffraction angle and the correspondent spot will move to a slightly different location. If the central deviation is of a similar order of magnitude as the spot size at the focal plane, the spot becomes elliptical.

This ellipticity will be stronger for a broader wavelength range (or shorter pulse duration) since each wavelength of the pulse spectrum will have a slightly different diffraction angle.

We also know that the zero order of the element (the fraction of light that goes undiffracted through the DOE) is wavelength-dependent, meaning it will increase while using a non-nominal wavelength by the same ratio. Therefore, while using an USP, we can expect an apparent zero order.

Using VirtualLab simulations, USP effects on various types of DOEs were studied. For each DOE, an optical setup was prepared that included a Gaussian source (with either a single wavelength or a wavelength spectrum), DOE, achromatic focusing lens, and a virtual screen to view the results located at the focus plane. The light was then propagated through the setup using classic ray-tracing propagation—a far-field physical optics propagation tool. For demonstration purposes, different input beam diameters were chosen to accentuate the possible outcomes.

Vortex lenses

Also called spiral phase plates, vortex lenses convert a Gaussian input profile into a donut- or square-shaped energy ring. Typical applications of a vortex lens include optical trapping, quantum optics, and high-resolution microscopy.

The spiral phase plate is a unique optical element whose structure is composed entirely of spiral or helical phase steps, with the purpose of controlling the phase of the transmitted beam. Its topological charge, denoted in the literature as m, refers to the number of 2π cycles (staircases) etched around a 360° turn of the diffractive surface.

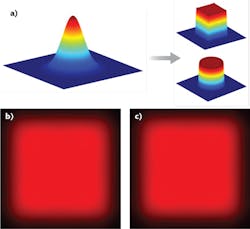

For a vortex lens element with m = 1, VirtualLab simulations show little effect on the DOE, regardless of whether the input is a single Gaussian pulse or a 100 fs ultrafast pulse (see Fig. 1). For circularly symmetric elements, the intensity is distributed along the ring-shaped spot, making it almost impossible detect any changes of the spot size. In other words, the changes do not occur in the azimuth plane, but rather in the radial plane—in which the changes are irrelevant to the shaping of the spot. Also, since this is not a periodic structure, effects such as ellipticity or zero order are irrelevant.

Diffractive axicons

An axicon transforms a laser beam into a ring shape (a Bessel intensity profile in the near field). It also images a point source into a line along the optical axis and increases the depth of focus. Because of its unique properties, the diffractive axicon is used in many applications, such as atomic traps, telescopes, and laser drilling.

Like the vortex lens, diffractive axicon output shows little variation whether the input pulse is Gaussian or ultrashort (see Fig. 2). The VirtualLab simulation and experimental practice points to similar results as for vortex lenses and assists in understanding this behavior—no zero order and no changes in the size and shape of the spot.Top hats

Top-hat beam shapers are used to transform a near-Gaussian incident laser beam into a uniform-intensity (flat) spot of either round, rectangular, square, line, or other shapes with sharp edges in a specific work plane. Typical applications are mainly in laser materials processing, including laser ablation, welding, and scribing for laser displays, cigarette filters, medical, and aesthetic laser applications.

For good-quality beam-shaper performance, the laser output should be single-moded (TEM00) with an M2 value under 1.3. Using this type of top-hat DOE, USP laser inputs do result in small changes in the shaped spot dimensions (see Fig. 3). Such changes are in keeping with the changes in the spectral regime, meaning that changes occur only at the edges of the spot (what we refer to as the transfer region of the DOE) and not in the center of the spot.Multi-spot beamsplitters

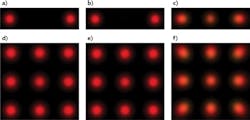

For a 1 × 2 beamsplitter (double spot), a grating-based DOE with a periodic structure is used. In general, beamsplitters are used in many applications, including lithography, perforation, fine-cutting, marking, and other materials processing applications.Depending upon the M × N configuration, USP laser inputs (for example, 5 fs) or high angles cause an ellipticity in the nominal round-shaped DOE output and show an apparent zero order in the center of the spot (see Fig. 4). Since this is a periodic diffraction-grating structure, each wavelength is diffracted according to this grating equation:

dsin =(θm) = m · λ

where d is the spacing between the slits, θm is the diffraction angle of wavelength λm, m is the diffraction order, and λ is the wavelength of operation. While using a USP laser with several different wavelengths, each wavelength will own a different diffraction angle and therefore will be formed in a different location. Therefore, we expect the spots to become elliptical instead of symmetrically round.

Another effect is an increased zero order that, as discussed previously, is wavelength-dependent. While operating a DOE with a different wavelength than the nominal one for which it is designed, we can always expect to observe a zero order in the pattern. This effect is more significant for an even number of spots, in which the zero-order is not a part of the pattern (as opposed to an odd number of spots).

From the simulations presented, USP laser inputs have little effect on most types of DOEs, unless the pulses are very short (a few femtoseconds). Nonetheless, the beam quality of the USP laser must also be taken into consideration. For a MM laser, the M2 parameter is higher than that of a SM laser, which reduces the speckling of the beam and masks the ellipticity effect for high-angle beamsplitters. The ellipticity of the input beam might affect the shape of the output spot (spot shape becomes more elliptical than round), and the beam diameter has an effect on the spot size and the separation angles.

REFERENCES

1. E. J. Hulbert, "What is ultrashort pulse laser technology? Applications of ultra-short laser pulses," Femtotechnology News (Oct. 30, 2014); https://goo.gl/mZzCpn.

2. See https://goo.gl/dXXkRf.

Israel Grossinger is founder and CEO, Shlomit Katz is an optical design engineer, Natan Kaplan is R&D manager, and Alex Skliar is VP of sales, all at Holo/Or, Rehovot, Israel; e-mail: [email protected]; www.holoor.co.il.