IR polarimeter improves detection of oil spills on water

Beyond major oil spills such as the 2010 Deepwater Horizon incident in the Gulf of Mexico, smaller oil spills are reported frequently and cleanup efforts depend on tracking the oil, assuming it is present on the surface of the water. Because the small thermal contrast between oil and water makes standard infrared (IR) imaging difficult, scientists at Polaris Sensor Technologies (Huntsville, AL) have demonstrated that even without thermal contrast, oil on water can be distinguished by strong polarization effects, making discrimination possible using an IR polarimeter.

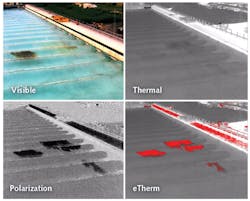

In the Pyxis long-wave infrared (LWIR) polarimetric instrument from Polaris, a microfilter array is mounted close to the microbolometer focal-plane array, allowing measurement of the thermal intensity of a scene as well as polarization magnitude and orientation. Because modern uncooled IR sensor arrays have low size, weight, and power and are based on emission characteristics of the signature, handheld use is possible, even at night. Operational tests at Ohmsett (the National Oil Spill Response Research and Renewable Energy Test Facility in New Jersey) on various volumes/types of oil spills under different tidal actions confirmed efficacy of polarimetric discrimination of oil (even diesel oil) with thicknesses between 40 μm and 1 mm in flat or wavy water, with contrast 3 to 50 times better than standard visible or thermal imaging alone. Pyxis also offers a color-enhanced eTherm mode that fuses polarimetric and thermal data. Reference: https://goo.gl/5J0Owt.

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.