Fiber-optic Sensing: Draw-tower FBGs in multicore fiber enable curvature sensing

Light signals from a series of fiber Bragg gratings (FBGs) inscribed along the length of a single-core optical fiber (SCF) can quantify the strain, temperature, and pressure experienced by that fiber. The technical team at FBGS (Jena, Germany) has taken the FBG sensing concept one step further by inscribing a high density of FBGs within a multicore fiber (MCF) using their draw-tower grating (DTG) technology to perform shape sensing.1

When inscribing FBGs in SCF or MCF, FBGS uses a continuous draw-tower process to both "write" and "coat" a single grating or array of gratings ranging in length from 1 to 10 mm and with adjustable center spacing and reflectivity of 0.01% to 25%. The inscribed gratings in the DTG-MCF have an identical configuration at the same axial position across all cores and exhibit the same reflection/transmission characteristics when unperturbed.

Bending-induced strain

Although an SCF with densely spaced DTGs can be used to sense variations in temperature, pressure, and strain when physically affixed to an object, it can only provide the axial location of the corresponding perturbation regardless of the SCF spatial orientation. To identify two- or three-dimensional (2D or 3D) spatial information, either multiple SCFs must be integrated into a multifiber bundle or, more elegantly, a single MCF can be used.

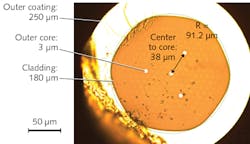

During bending, the FBGs on the outer cores of the MCF experience a longitudinal stretch or compression with respect to the central axis, causing a positive- or negative-induced strain change, respectively, from which the local curvature can be calculated based on physical parameters of the fiber cores (see figure). To reconstruct the overall curvature profile, the data is plotted as a function of FBG position along the fiber.

Signal interrogation

The signals from the DTG-MCF are routed to and from the individual cores by a fan-out device to the channels of a designated interrogator. For gratings with different wavelength profiles, signal interrogation requires a wavelength-division multiplexing (WDM) detection system wherein the wavelength shifts as a function of relative strain are calculated and calibrated for each core using a special algorithm. For gratings with a single wavelength profile, optical frequency domain reflectometry (OFDR) can detect 0.01% reflectivity with detection speed around 100 Hz, which allows for measurement of several thousand FBGs.

In contrast, WDM-based interrogation is typically restricted to the measurement of 80 FBGs on each channel and with a speed up to several kilohertz. Selecting criteria for the right platform is application-specific with considerations for overall cost and accuracy.

FBGS director of business development of biomedical and special markets Nadhir Kosa says, "Several applications in the healthcare, industrial, and aerospace markets can readily capitalize on exploring the advantages of distributed, multiplexed sensors, especially when conventional and even single-point fiber-optic sensors cannot comply with their basic requirements. DTG-MCF sensors are mechanically robust, lightweight and compact, immune to ionized radiation, and inert-beneficial attributes when integrated with advanced minimally invasive devices targeted for clinical diagnostic, therapeutic, or monitoring applications, as well as structural health monitoring of industrial, oil and gas, and avionic assets."

REFERENCE

1. B. Van Hoe et al., "Distributed strain and curvature measurements based on tailored draw tower gratings," Proc. AVFOP, paper ThA2.1 (Nov. 3, 2016).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.