Beam Characterization: Laser power meter measures 500 kW using radiation pressure

As the highest-power commercially available lasers edge towards megawatt-level outputs (the multimode YLS ytterbium-doped CW fiber lasers manufactured by IPG Photonics of Oxford, MA can be made to have power levels of up to several hundreds of kilowatts), the instruments used to measure their optical characteristics must adapt to accommodate such high powers without self-destructing.

One way to do this might be to base the instrument on an alternate principle of measurement-especially valuable would be a technique that becomes easier and more robust as laser power gets higher. A well-known example of this approach is the BeamWatch beam-diagnostic instrument made by Ophir-Spiricon (North Logan, UT), which images Rayleigh-scattered light from a high-power laser beam in air to determine the beam's focus and other characteristics—the more powerful the beam, the easier its path is to image.

Measuring the optical output of a high-power laser is more difficult as the laser power goes up, as this type of measurement is best done via calorimetry, or carefully characterizing the amount of heat produced in a cooled beam-absorbing target. Even so, the power of a 100 kW beam can be measured in this way.

Radiation pressure

Recently, Scientech (Boulder, CO) unveiled a laser power meter also based on an alternate principle: measuring the pressure that the light from a high-power laser exerts when it is reflected from a mirror. Developed with the National Institute of Standards and Technology (NIST, also in Boulder),1, 2 the radiation-pressure power meter (RPPM) has measured beam powers exceeding 500 kW with 1% accuracy in a device the size of a breadbox, according to Scientech engineer Robert Lee, who worked with NIST on the device.

The path to the collaboration was through one of Scientech's other products: precision electronic weighing systems. "Dr. John Lehman of NIST's Applied Physics Division contacted us about the possibility of measuring radiation pressure using one of our laboratory scales," says Lee. "We have a long history of working with NIST and our unique position of manufacturing laser power meters and analytical weighing scales was known to him. We were able to build a prototype unit and test it at their facility with their 10 kW laser to prove the concept." (Note: NIST does not endorse this or any other manufacturer's instruments.) The RPPM is calibrated to a 1 g Ultra Class mass with a certified accuracy of ±.02 mg, or 0.002%, Lee says.

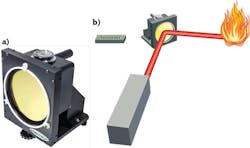

The force exerted by a beam reflecting from a mirror is linearly proportional to the beam's power multiplied by the cosine of its angle from normal incidence. Thus, this type of meter can be used at a 45° angle, making it a simple 90° beam deflector (see figure). This is exactly the configuration used in the tests done with 500 kW of optical power. These tests were carried out by Y. K. Bae at Y. K. Bae Corp. (Tustin, CA), an outfit known for its development of a photonic laser thruster, a device that also works via radiation pressure. The 500 kW of recirculating optical power produced a photon pressure of 330 mg.3

"Below 1 kW, the feebleness of the force limits the ability of a magnetic-force restoration sensor to measure it accurately," Lee says. "Above 10 kW, it becomes an economical alternative to other more limited technologies. I see this as being an invaluable tool in the development of directed-energy devices and beneficial for monitoring high-power laser welding. The limiting factor will be in mirror quality, as heat is not only conducted back into our instrument but can be a source of turbulence in non-vacuum environments."

REFERENCES

1. P. A. Williams et al., Opt. Lett., doi:10.1364/ol.38.004248 (Oct. 15, 2013).

2. See www.nist.gov/pml/div686/laser-102213.cfm.

3. Data courtesy of Y. K. Bae Corporation.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.