Low-cost 2-micron laser scalpel uses ceramic gain materials

Scientists from the Russian Academy of Sciences and Nizhniy Novgorod State University (both in Nizhniy Novgorod, Russia) and NTO IRE-Polus and the Moscow Institute of Physics and Technology (both in Moscow, Russia) have developed a ceramic-based laser that cuts tissue with minimal trauma and is at least two times less expensive than lasers using high-quality crystal-grown lasing materials.

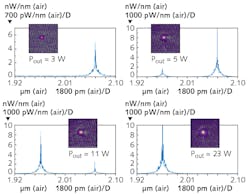

Most 2 μm lasers—proven superior for surgical applications because of easy absorption of this wavelength by water molecules in human tissue without large penetration depth—use thulium (Tm)- or holmium (Ho)-doped laser glasses to achieve high peak powers. However, the Russian scientists pumped a thulium lutetium oxide (Tm3+:Lu2O3) ceramic laser with a 1670 nm Raman-shifted erbium fiber laser (RSEFL) to achieve both continuous-wave (CW) and Q-switched operation with excellent beam quality. Specifically, 23 W CW with 59.1% optical-to-optical conversion efficiency and 15 W average power for Q-switched mode with 40–80 ns pulse duration and 15 to 30 kHz repetition rate were observed for lasing at 1966 and 2064 nm, with different oscillation spectra and far-field profiles as a function of laser output power. The Lu2O3 sesquioxide ceramic overcomes the problem of single-crystal growth at high melting temperatures (above 2400°C), and allows the preparation of larger gain components with higher thulium concentrations at lower cost for more economical surgery and lithotripsy compared to 2 μm crystal or fiber lasers. Reference: O. Antipov et al., Opt. Lett., 41, 10, 2298–2301 (May 15, 2016).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.