Specialty Fibers: Mid-IR hollow optical fibers assist spectroscopy applications

Although mid-infrared (mid-IR) lasers have seen continuous technological improvement over the last decade, mid-IR optical fibers and other supporting optical components—so critical to the process of transporting mid-IR energy to the work surface or sample under test—are oftentimes difficult to source.

To make sure that its hyperspectral imaging, spectroscopy, and gas-sensing systems did not suffer from inadequate mid-IR beam delivery, OptoKnowledge Systems (Torrance, CA) transitioned technology developed at Rutgers University (New Brunswick, NJ) in the production of its family of mid-IR to long-wavelength-IR (LWIR) optical fibers.

By depositing silver and silver iodide coatings on the interior of a capillary tube, OptoKnowledge fabricates multimode hollow-core (zero back-reflection) fibers that operate from 2 to 14 μm, with single-mode versions available for operating wavelengths longer than 5 μm. With internal bore diameters ranging from 200 to 1000 μm, length-dependent loss of 4.0 to 0.1 dB/m, output divergence half-angles from 50 to 30 mrad, and accommodating 5–100 W power levels, respectively, these mid-IR optical fibers are now being proven instrumental for a variety of spectroscopy-related applications.

Trace-gas sensing

Using OptoKnowledge fibers with single-mode operation from 5.1 to 10.5 μm, researchers at the University of Bari (Bari, Italy) have demonstrated part-per-trillion-level sulfur fluoride (SF6) detection with a quartz-enhanced photoacoustic spectroscopy-based sensor with single-mode fiber-coupled quantum cascade laser (QCL) excitation.1 The single-mode hollow fibers deliver the probe QCL beam and improve the beam quality, leading to significantly better signal-to-noise ratio (SNR) compared to using a pinhole.

Combustion diagnostics

Stanford University (Stanford, CA) researchers are studying noninvasive combustion diagnostics via mid-IR absorption spectroscopy.2 Hollow fibers deliver the beam from a remote location to harsh, high-vibration environments such as a scramjet combustor. In one set of experiments, OptoKnowledge produced a tailor-made dual-fiber probe that delivered light from two separate laser sources between 4 and 5 μm in a common connector.

Glucose monitoring

Working in the Mid-Infrared Technologies for Health and the Environment (MIRTHE; Princeton, NJ) group, Sabbir Liakat and his team are developing noninvasive glucose-monitoring instruments that use mid-IR hollow fibers to both deliver the probe laser beam and collect the reflected signal.3 The fibers—coated for optimal transmission from 8 to 10 μm—enable the laser source to be located remotely from the probe tip and reduce SNR by mitigating the effects of vibration inherent with making measurements on live patients.

Isotope analysis

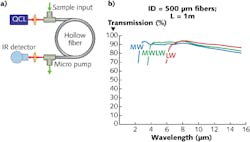

Pacific Northwest National Laboratory (PNNL; Richland, WA) has developed an isotope-analysis system using hollow fiber as the gas cell that confines the sample and guides a probe laser from a QCL source to an IR detector (see figure).4 This capillary absorption spectrometer (CAS) has near-unity overlap between a sample and a tunable probe laser (the beam interacts with nearly 100% of the sample compared to other schemes that just transect a portion) for high-precision analysis of extremely small sample volumes. OptoKnowledge is working to transition this technology to industry and develop complete systems.

"Mid-IR spectroscopy is an extremely powerful technique that is able to exploit the unique molecular fingerprint of different species for applications ranging from measuring biomarkers in human breath to looking for evidence of past life on Mars," says Jason Kriesel, lead scientist at OptoKnowledge. "Our hollow fibers are providing a new tool that is improving the utility and performance of such systems and we are now working to push the technology in multiple directions, such as improving single-mode functionality, increasing the transmission, and extending the wavelength range of our current mid-IR fiber technology while also developing new fiber structures for terahertz-frequency lasers."

REFERENCES

1. A. Sampaolo et al., Opt. Express, 23, 1, 195–204 (2015).

2. R.M. Spearrin et al., "Mid-infrared absorption sensor for measurements of CO and CO2 in propulsion flows," 52nd AIAA Aerospace Sciences Meeting, National Harbor, MD (Jan. 2014).

3. S. Liakat et al., Biomed. Opt. Express, 5, 7, 2397–2404 (2014).

4. J. F. Kelly, R. L. Sams, T. A. Blake, and J. M. Kriesel, "Further developments of capillary absorption spectrometers using small hollow-waveguide fibers," Proc. SPIE, 8993, Quantum Sensing and Nanophotonic Devices XI, San Francisco, CA, 89931O (Feb. 1, 2014).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.