Cryolasers target >80% power conversion efficiency

LIFE, HiPER, and ELI high-energy-class lasers all depend on ultra-efficient laser-diode bars with the highest output powers. The laser-bar power-conversion efficiency ideally exceeds 75% (versus 65% state of the art) at a bar power of greater than 800 W (versus 400 W state of the art). The Ferdinand-Braun-Institute (FBH; Berlin, Germany) is currently developing laser-diode bars that will allow these stringent requirements to be met by using designs optimized for operation below the freezing point of water.

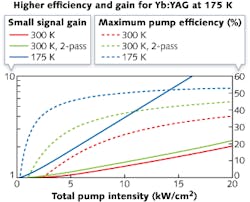

When laser diodes are operated at low heat-sink temperatures (below 0ºC or 273 K), optical gain increases and nonradiative recombination is reduced, thus lowering threshold. The lower threshold current corresponds to lower carrier densities in the active region, reducing absorption and suppressing leakage effects, leading to slope efficiency (useful photons out per electron in) nearing 100% as the temperature decreases. However, simultaneously the series resistance at lower temperatures increases, limiting efficiency at high currents and powers. The design challenge is to substantially reduce the series resistance while maintaining high optical performance. To date, record operating powers of 1.7 kW have been achieved at -55°C in single 975 nm laser bars, where conversion efficiency is 50%. The group is currently experimenting with design and material quality improvements, seeking to enhance the efficiency at 1.6 kW to greater than 80% by exploring novel designs with low p-side waveguide losses. Internal gratings are also planned to narrow the optical spectrum enabling more effective pumping of the laser crystals used in LIFE, HiPER, and ELI. Contact Paul Crump at [email protected].

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.