PHOTONICS APPLIED: MATERIALS PROCESSING: Objective lenses for laser materials processing have high thermal stability for high-power lasers

PETER TRIEBEL, LUTZ REICHMANN, and HELMUT BERNITZKI

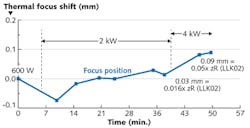

The latest high-power continuous-wave (CW) disk and fiber lasers emitting in the 1030 to 1070 nm wavelength range provide multiple kilowatts of energy for many sophisticated processes; the small spot sizes and high intensities of these lasers enable high-speed materials processing. These highly efficient processes are very sensitive to changes in performance of the system optics, such as an energy-dependent focus shift.

Effect of thermal lensing on optical performance

Focusing high-power lasers with high beam qualities (M2 <1.5) has some implications for the optical system. Absorption of the beam by even a single optical element in the system will result in a thermal shift of the beam focus position.

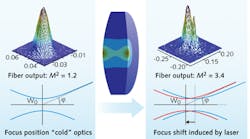

In addition to the deleterious effect of the focus shift itself, the beam quality itself decreases.1 A sophisticated model can simulate the thermal behavior of such a lens system; a model calculation (see Fig. 1) shows an increase in the M2 of a laser beam from 1.2 to 3.4 due to optical absorption by a focusing lens. This increase is the result of a higher-order wavefront distortion induced by the absorption-induced change in the phase profile of the lens, caused by the change in refractive index as a function of temperature (dn/dT). Methods to avoid this temperature-induced focal shift can be added to a pre-existing focusing system and are often used in scanning and high-speed applications.

Lower absorption by improved manufacturing

The discussed approach to minimize focus shift is to further decrease the optical absorption of the lens, both within the lens and at its surfaces. Along these lines, an extensive test program for characterization and identification of feasible optical materials was carried out at Jenoptik. Tested optical materials (including fused silica and various sorts of optical glasses) were selected to show lowest absorption coefficients in a wavelength range between 1030 nm and 1070 nm.

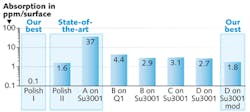

To characterize the test-set comp onents, different absorption-measurement methods were used and compared. The reference method is the laser-induced deflection (LID) method developed by the Institute of Photonic Technology (IPHT) in Jena, which relies on a high-power pump beam to cause thermal perturbations and a low-power probe beam to measure them.2

The absorption values measured by the various methods (see Fig. 2) were analyzed along with a LID wavefront measurement using a 400 W singlemode pump fiber laser at 1070 nm wavelength. The results show clear evidence for better performance resulting from improvements in the optical polishing process, as well as by lowering the optical coatings' absorption. The values of the absorption of the best polished surface are below 0.1 part per million per surface (ppm/surface) compared with state-of-the art values of 1.6 ppm/surface. The absorption values of the antireflection coating are below 2 ppm/surface, compared with state-of-the-art values of 37 ppm/surface.Application to production lenses

The knowledge gained from these tests was applied to improve design and optimize Jenoptik's Silverline F-Theta lens series (see Fig. 3), minimizing the focal shift of the lenses. These lenses are designed for applications at wavelengths from 1030 to 1080 nm and 515 to 540 nm and are suited for use with high-power (up to 5 kW) fiber and disk lasers as well as short-pulse lasers with picosecond or femtosecond pulse durations. Short-pulse laser applications at wavelengths of 532 and 1064 nm at high pulse energies include the processing of chemically hardened glasses and sapphire materials.ACKNOWLEDGEMENTS

We would like to thank the German Ministry of Education and Research (BMBF) for funding the project BriPro (FKZ13N1111) and the company Trumpf Laser GmbH for providing the measurement data as well as the discussions on the achieved results.

REFERENCES

1. F. Abt, A. Heß, and F. Dausinger, "Focussing of high power single mode laser beams," ICALEO, 202 (2007).

2. C. Mühlig and S. Bublitz, Opt. Eng., 51, 12, 121812 (Sept. 14, 2012).

Peter Triebel is product manager, Optics for Laser Material Processing and Health Care & Life Sciences; Lutz Reichmann is manager, Mechanical Design of Optics; and Helmut Bernitzki is senior expert, all at Jenoptik Optical Systems GmbH, Jena, Germany; e-mail: [email protected]; www.jenoptik.com/en-optical-systems.