PHOTON COUNTING: Upconversion imager measures single mid-IR photons

JEPPE SEIDELIN DAM, PETER TIDEMAND-LICHTENBERG, and CHRISTIAN PEDERSEN

In recent years much effort has been put into the development of light sources in the mid-infrared (mid-IR) spectral region (2 to 5 μm). This has resulted in novel systems like quantum-cascade lasers (QCLs) and broadly tunable or broadband light sources using nonlinear frequency conversion, either in optical fibers or in nonlinear crystalline materials.

On the detector side, there have not been similar technology breakthroughs. The most sensitive IR detectors today are based on exotic semiconductor technology such as indium antimonide (InSb) or mercury cadmium telluride (MCT). High-quality detectors of these sorts are expensive and suffer from high dark currents. Dark current can be somewhat alleviated by extreme cooling; even so, dark currents measured in millions of electrons per second are common for cooled devices.

Comparing the performance of today's state-of-the-art IR detectors to high-quality detectors for the visible/near-IR region shows a striking contrast, as the latter can have dark currents in the range of 0.001 electrons per second. This discrepancy in sensitivity has resulted in a strong interest in the use of low-noise, high-quantum-efficiency photon-upconversion techniques. Various systems have been tested, based on three- and four-wave mixing schemes both for point and image detection.

Wavelength upconversion can be performed as three-wave mixing in a nonlinear medium using an intense laser field. For a point detector arrangement, this can be accomplished in a waveguide configuration.1 Demonstrated performance of waveguide-upconversion techniques still show considerable dark noise, even when working in the near-IR (in the vicinity of 1.5 μm).2 While these methods still have added dark noise, they have allowed the use of single-photon-sensitive devices well outside of their specified wavelength operation range.

Dark-noise issues in IR imaging

Conventional detection schemes for IR radiation include microbolometers, which rely on minute temperature changes induced in a 2D nanophotonic sensor device when IR radiation is absorbed. Microbolometers exist both as cryogenically cooled and uncooled devices.

Other mid-IR detectors rely on semiconductor materials such as InSb and MCT, which must be cooled to achieve acceptable noise levels. Both these types of semiconductor devices can measure temperature differences down to about 15 mK. This is a very impressive sensitivity; however, when calculating how many photons this temperature difference corresponds to, the result is on the order of 108 photons/pixel/s when taking into account the detector's pixel size and bandwidth and the f-number of the required lens. In other words, measuring temperature differences is very different in scale than counting single photons.

The dark noise in the previously mentioned mid-IR detectors has multiple origins. These include thermal radiation coming from within the camera housing, since the pixel elements cannot discriminate between photons coming from outside or from the inside. In addition, the semiconductor-type detectors have very small bandgaps in the IR, increasing their susceptibility to thermal excitation of electrons. The effects of these noise sources are reduced by cooling the chip and its surroundings.

In recent work, the authors have demonstrated how both coherent and incoherent mid-IR radiation can be converted to near-visible wavelengths with high quantum efficiency.3 The conversion module can be thought of as a kind of camera objective that can be attached directly to the near visible camera (see Fig. 1). The realized conversion module is a relatively compact and portable system that can be easily transported or used as a handheld device.

The actual wavelength conversion is taking place inside a magnesium-doped periodically poled lithium niobate (MgO:PPLN) crystal. To reach high conversion efficiencies, the nonlinear crystal must be placed in a powerful laser beam. In the present realization, this is done by placing the crystal inside a laser cavity, where a circulating laser power of 100 W is obtained by pumping a Nd:YVO4 laser with a standard 4 W, 808 nm broad-area laser diode. This system has now been working for several months without any realignment.

The wavelength upconversion is performed with only extremely small added dark noise, even when operating at room temperature. In fact, to measure any noise at all we need to heat up the crystal to well above room temperature (see Fig. 2).The dark-noise levels at room temperature are estimated according to theoretical predictions. The upconverter has a limited bandwidth, so if the signal of interest is narrowband, the upconversion can be tuned to that specific wavelength band, further suppressing unwanted noise. This is in strong contrast to direct IR detection systems, where noise from a broad spectral range typically contributes to the overall dark noise.

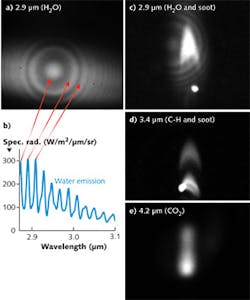

The spectral functionality of the system is illustrated in an experiment in which a candle and a butane flame are imaged at different wavelengths (see Fig. 3). Signals down to the single-photon level can be measured with this system when a highly sensitive visible/near-IR camera is used.The suppression of dark noise is attributed to the transparent material used—that is, a material with ideally zero emissivity. Such a material will not absorb or emit photons. Shifting the photon energy via the nonlinear upconversion process to the visible or near-IR wavelength range, where dark current is strongly reduced, results in low-noise detection. This is in contrast to direct IR detection using a low-bandgap semiconductor.

In the MgO:PPLN nonlinear crystal used in our system, the energy of a laser photon is added to each of the mid-IR photons to generate near-visible photons at the sum frequency. The upconversion is done not at an image plane but rather in an infinity-corrected geometry. As a result, the image information is contained in the angle of the incoming light; therefore, thermal radiation coming from the inside of the conversion module ends up outside the upconverted image. This is in sharp contrast to conventional mid-IR detectors. The combination of these two effects is responsible for the extremely low noise levels compared to any other room-temperature mid-IR detector.

Our approach gives rise to some differences worth mentioning in addition to the extremely low noise levels. For one, it opens up the possibility of detecting image information using photon counting, unlike the conventional waveguide upconversion approach where a singlemode (single-point-detection) geometry is dictated by the waveguide. Having the upconversion process in an imaging geometry further allows for spatial filtering of noise, if the angle of the incident light is known. In this way, the noise level can be restricted to the contribution from a few spatial elements, if the incoming light is well-collimated and matches the size of the upconversion laser field.

While the upconversion method has been demonstrated to work in the range from 2.9 to 4.2 μm, this range can easily be extended to shorter wavelengths using suitable poling periods of the MgO:PPLN crystals. Our 20-mm-long crystals are produced by Covesion (Romsey, England) and have five different poling periods ranging between 21 and 23 μm.

To cover shorter wavelengths, new crystals with shorter poling periods are required, while to cover significantly longer wavelengths a different type of nonlinear crystal is required, as lithium niobate is not transparent much beyond about 5 μm. Because the upconversion process literally works at the speed of light (the photons are converted in a single pass through the nonlinear crystal), the temporal resolution achievable is set by the visible/near-IR light detection system used after the upconversion module.

Numerous new applications of this novel detector scheme are possible. For example, the design has already been implemented as a compact, field-deployable, highly sensitive IR spectroscopic device that can be produced at competitive prices (its basic components resemble those found in a green laser pointer). Because the need for cryogenic cooling has been eliminated, operational costs of this system are significantly less than those for conventional IR-detection devices.

REFERENCES

1. X. Liu et al., "Bridging the mid-infrared-to-telecom gap with silicon nanophotonic spectral translation," Nature Photon., 6, 667 (2012); doi:10.1038/nphoton.2012.221.

2. E. Pomarico et al., "Room temperature photon number resolving detector for infrared wavelengths," Opt. Expr., 18, 10750 (2010); http://dx.doi.org/10.1364/OE.18.010750.

3. J. Seidelin Dam et al., "Room-temperature mid-infrared single-photon spectral imaging," Nature Photon., 6, 788 (2012); doi:10.1038/nphoton.2012.231.

Jeppe Seidelin Dam is a researcher and Peter Tidemand-Lichtenberg is an associate professor at DTU Fotonik, the department of photonics engineering at Technical University of Denmark, DK-4000 Roskilde, Denmark; e-mail: [email protected]. Christian Pedersen is the group leader of the Optical Sensor Technology group at DTU Fotonik.