NANOPOSITIONING: Long-travel piezomotors ‘reboot’ the motion-control toolbox

A confluence of new piezo-based technology has breathed new capability into the nano- and micropositioning world. Piezo actuation is increasingly suitable for applications formerly addressable only by magnetic motors and the technology offers significant benefits in terms of size, speed, fieldlessness, reliability, vacuum compatibility, resolution, dynamics, and reliability. These benefits in turn enable significant advances in existing and new applications.

Applications in a variety of fields require positioners to control more degrees of freedom with increasing dynamic and static accuracy; they must manage faster throughputs across longer travels to meet financial metrics. In many applications, compactness is prized, yet high speeds are demanded.

Examples of these applications abound. For one, optical assemblies of escalating sophistication require multiple axes of nanoprecision alignment that must remain aligned for months of round-the-clock usage. For another, emerging nanoimprint lithography methods demand exquisite positioning and trajectory control and must retain alignment integrity under significant physical and thermal stresses. And applications ranging from cell-phone cameras to endoscopy and fluid delivery require exceedingly small but stiff, responsive, and reliable positioning of optics, probes, and shutters. Until recently these conflicting requirements have had no solution.

Nanometers over millimeters

When precision is needed, piezoelectric actuation is the default choice. Similarly, when high force or high dynamics is required, piezoelectric actuation represents the gold-standard. Piezostack actuators, however, offer limited maximum travel, on the order of 0.1% of the stack’s length. Effective flexure lever-amplification approaches have been devised that help provide travels up to 2 mm. The downside is that the stiffness of lever mechanisms diminishes as the square of the lever ratio. This effect limits the bandwidth and thus the tracking performance of traditional servo control techniques. So, demands for longer travels plus faster actuation or higher holding force are at cross-purposes. Furthermore, at some point the granularity of the driving digital-to-analog converter (DAC) begins to show, limiting coarse positioning resolution or introducing bit-transition noise in position waveforms.

One type of novel control technology, digital dynamic linearization, is a nontraditional algorithm integrated into the latest digital nanopositioning controls that virtually eliminates following errors in repetitive motion patterns and scanning of these long-travel nanomechanisms. The controller integrates the algorithm into the metrology and servo logic, which optimizes the internal command generated for a repetitive waveform according to the error signal detected with the internal sensor. The user controls a brief (typically less than one second) auto-optimization (or a reload of previously-saved optimizations) when application changes occur. After this, following errors are reduced to approximately the noise level of the system. This capability is supported by internal waveform generators and software drivers such as component-object-model objects, dynamic-link libraries, and LabVIEW libraries.

Piezo actuation is roughly proportional to applied voltage, typically generated by a DAC driving an amplifier. The number of addressable positions for a piezo mechanism is 2b, where b is the bit-width of the digital input. Traditionally, the resolution of the nanopositioner can be no better than its travel divided by this number. With long-travel flexure nanopositioners, achieving tight resolution goals requires higher and higher DAC bitness.

Until recently, a DAC’s limitations were permanent characteristics of the specific chip chosen by the designer. Popular personal-computer analog input/output (I/O) interfaces like those from National Instruments (Austin, TX) typically top out at 16 bits, providing 65,536 possible output-voltage states, with update rates to several million per second and useful waveform and synchronization capabilities, plus compatibility with popular programming languages like C++, VisualBASIC, and LabVIEW. Engineers designing controls for OEM applications might choose a 20- or 24-bit DAC for their custom circuit design, but they can present drift issues, noise, or other drawbacks. Sometimes a new design is not economically practical, necessitating use of lower-bit legacy DACs, which is potentially problematic when used with highly leveraged lead zirconate titanate (PZT) mechanisms.

The recently introduced, patented HyperBit technology leverages the underutilized time-domain capability of current DACs, adding up to 11 additional bits of physical positioning resolution. HyperBit uses modulation of the DAC’s least-significant bits to accomplish this. For example, the least significant bits can be dithered using pulse-width modulation at a high rate. The result is higher positioning resolution without tradeoffs. Many mechanisms and devices can benefit; see the video “PI HyperBit” demonstrating this effect using a commonplace panel meter at www.laserfocusworld.com/resourcecenter/video.html. For ease of implementation, this technology is now built into the industry’s first LabVIEW library for analog nanopositioner interfacing.

Nanometers over centimeters

Applications needing longer travels than can be addressed via lever amplification of piezo-stack actuators, engineers have developed an array of new technologies based on novel configurations and actuation modes of piezo ceramics. One solution is resonant piezomotors, in which high-frequency excitation drives one or more resonant modes in a ceramic wafer, conferring a micron-scale oscillatory motion to a friction pusher tip affixed at an antinode. The pusher tip, oscillating like a miniature pogo-stick with nanoscale amplitudes and frequencies of hundreds of kilohertz, can then be preloaded against a guided workpiece, driving long-travel motion with dynamical behavior somewhat similar to that of DC servomotors.

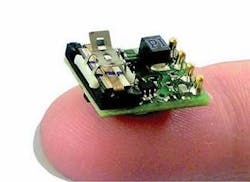

Motion-control providers in many countries over several decades have commercialized a wide assortment of linear- and rotary-motion configurations, both open- and closed-loop. By eliminating lead-screws, their inertia, and associated linkages and structures, such mechanisms can be very compact and responsive. For example, off-the-shelf linear stages can provide 19 mm of travel at up to 500 mm/s and 10 G acceleration with a 0.1 µm resolution linear encoder, all in a package 35 mm square. Even smaller mechanisms have been devised, such as the self-guided piezomotor for miniature camera and endoscopy applications (see Fig. 1).

The in-position stability of resonant piezomotors is superior to conventional stages because the actuator acts as a brake when quiescent. The other signature advantages of piezo actuation, such as vacuum-compatibility and long life, also apply. Another advantage of piezo technology extended to resonant piezomotors is that they do not create electromagnetic fields, nor are they influenced by themotherwise known as fieldlessness.

The drawback to resonant piezomotors has traditionally been that they are difficult to control. Many types of motors exhibit a linear stimulus-to-velocity curve. A small amount of friction present in most DC-motor mechanisms means a small but nonzero stimulus produces zero velocity—a departure from the desired linearity. Conventional control technology usually overcomes this “stiction” with an integrating filter that escalates the stimulus as needed.Resonant piezomotors have a similar drawback, though the cause is not friction. A certain threshold of stimulus must be applied to the resonant piezomotor before motion begins. This deadband behavior is great for in-position stability, but is at odds with conventional proportional-integral-derivative (P-I-D) controls: applying adequate integrator gain to overcome the deadband effect causes an “in-motion” response delay. This can be addressed with advanced controllers that automatically switch between gain sets, but they require additional time and expertise to set up and changes to the system load or dynamics require painstaking retuning.

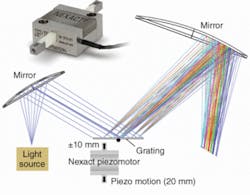

At SEMICON West 2008, PI introduced an automatic adaptive-control technology for resonant piezomotors. Requiring no setup or tuning, it is based on patented neural-network technology, enabling robust and consistent servo control of resonant piezomotors even in applications with varying loads and dynamics (such as in handling and shuttling applications), with precise tracking performance (see Fig. 2).Piezo walking drives

A walking actuator is based upon piezo elements that act in longitudinal and transverse directions. These elements can be compressed against a longitudinal rod to confer motion. One familiar progenitor of this family of mechanisms was the Burleigh Inchworm. More recently developed mechanisms offer extraordinary stiffness and holding force and are optimized for reliability in applications requiring long-term position hold while providing centimeters of travel with picometer-class resolution.

An even newer solution uses cost-effective bender-type piezo elements. Size and cost are substantially reduced; power-off stiffness is still remarkable, with 10 N of holding force. This design also provides centimeters of travel range and picometer-class resolution, ideal for applications like optics positioning in microlithography and sample positioning in electron microscopy (see Fig. 3). In the case of both these mechanisms, motion occurs in two modes: a long-travel stepping mode, and a fine-motion analog mode, in which the actuator elements are sheared but not stepped, providing subnanometer positioning capability.

Hybrid mechanisms

While the mechanisms discussed so far can displace magnetic motors, piezo actuation can also be combined with them for coarse/fine motion. Traditional “stacked” coarse and fine mechanisms operate independently; the piezo mechanism greatly improves the minimal incremental motion capability of the system, but the overall repeatability is no better than the motorized stage alone.

The advent of linear encoders with nanometer-scale resolution has allowed construction of hybrid mechanisms in which the coarse and fine mechanisms share the same feedback sensor. Coordinated by advanced controls, such hybrids can provide piezo-based repeatability and fast dynamics over many centimeters of travel.

REFERENCES

1. S. Jordan et al., Proc. 4th Int’l. Symp. Nanomfg., Cambridge, MA, 166 (2005).

2. P. Pertsch et al., ACTUATOR 2006, Bremen, Germany, 527.

3. R. Gloess, ACTUATOR 2006, Bremen, Germany, 668.

4. K. Spanner and S. Vorndran, IEEE Proc. ASME Int’l. Conf. Adv. Intelligent Mechatronics 2003, Kobe, Japan.

5. S. Jordan and H. Marth, Proc. ASPE 2007, Dallas, TX.

About the Author

Scott Jordan

Head of Photonics, PI (Physik Instrumente)

Scott Jordan is Head of Photonics at PI (Physik Instrumente; Auburn, MA).