Ultrafast lasers have reached a new level of maturity. They are now commercially available with average powers of more than 100 W from stock; soon, you'll be able to work with systems of several kilowatts average power. Plus perfect beam quality. Plus process technology.

This is what the huge Fraunhofer Cluster of Excellence Advanced Photon Sources announced last year and now they have gone for it. The project unites the forces of not less than 12 Fraunhofer institutes. The laser sources are developed by Fraunhofer IOF in Jena and Fraunhofer ILT in Aachen, Germany.

Coherently combined fiber laser system

In December 2018, a team headed by Jens Limpert from Fraunhofer IOF and Friedrich Schiller University Jena presented their latest record: A fiber laser system with 3.5 kW average power and a pulse duration of 430 fs after amplification. As they note: "The system is turn-key operable, as it features an automated spatial and temporal alignment of the interferometric amplification channels."It is the collaboration between the Fraunhofer IOF and the Jena university that resulted in a 200 W system with 6 fs pulses in 2016 and a 4.3 kW single mode continuous-wave fiber laser in 2017, to name but a few of their achievements.

The new record-winning system is based on an all-fiber amplifier setup that uses a coherent combination of four separately amplified beams. A fiber seed laser emits pulses at a wavelength of 1047 nm and a repetition rate of 80 MHz; these pulses are stretched, shaped and pre-amplified to 60 W average power before they are split into four separate beams. These four channels go into main amplifier stages, each pumped with up to 1.6 kW at 976 nm.

The main trick comes after this amplification: The four linearly polarized beams are coherently coupled (or superposed) in a tree-type configuration of 50/50 beam splitters. This requires sophisticated alignment: Three of the beams are equipped with two motorized mirrors and a translation stage each to enable adjustment and optical path length correction. And there is active phase stabilization as well as automated optimization of spatial and temporal overlap. You may find all details in their publication.

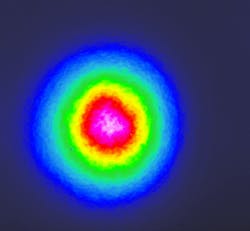

The beam after amplification looks really nice: The beam parameter product (M²) before the final compression is 1.07 in the x direction and 1.06 in the y direction (see figure). After compression it diminishes slightly to 1.24 in x and 1.10 in y. The researchers found a quality issue on the steering mirror as the reason for this deterioration.

What's next? "We want to scale the system up to 10 kW later this year," Limpert told me.

Two application labs will open in 2019

People have developed ultrafast lasers for decades in university labs. The German Fraunhofer Gesellschaft is a society "for the Advancement of Applied Research" and so their ambition goes beyond pure academic curiosity. The teams at the Fraunhofer IOF in Jena and at the Fraunhofer ILT in Aachen plan to start application labs within the cluster Advanced Photon Sources to make use of their respective laser sources. Together with the 10 other Fraunhofer institutes, they form a virtual institute to act with external partners and clients in an optimized organizational structure.

The application labs will offer the sources and related process technology for partners and clients to develop their application. Among other ideas, the Jena team plans to set up a beamline for the generation of coherent extreme-UV (EUV) radiation. This would allow for high resolution imaging of biological and semiconductor probes. They think about testing EUV lithography masks.

The Fraunhofer teams will be working on a new generation of lasers with high average power and pulses shorter than 1 ps for industrial applications. The two teams will be developing fiber (Jena) and disk or slab (Aachen) amplification technologies. At the same time they will be working on process technology and applications. The application labs in Aachen and Jena are under construction now, Aachen will open on September 18, while the Jena facility is scheduled for the fourth quarter of 2019. It’s an ambitious but also very promising plan.

About the Author

Andreas Thoss

Contributing Editor, Germany

Andreas Thoss is the Managing Director of THOSS Media (Berlin) and has many years of experience in photonics-related research, publishing, marketing, and public relations. He worked with John Wiley & Sons until 2010, when he founded THOSS Media. In 2012, he founded the scientific journal Advanced Optical Technologies. His university research focused on ultrashort and ultra-intense laser pulses, and he holds several patents.