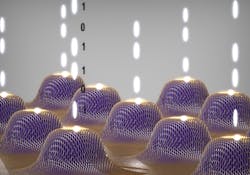

On-demand room-temperature single-photon array produces precisely located photons

Physicists at The City College of New York (CCNY) have used atomically thin two-dimensional materials to realize an array of on-demand quantum emitters operating at room temperature that can be integrated into next-generation quantum-communication systems.1 CCNY professors Carlos Meriles and Vinod Menon and their colleagues used hexagonal boron nitride (hBN) placed on nanopillars to demonstrate single-photon emission at the pillar locations.

In simplest terms, the breakthrough allows one to know where the single-photon emitters are located. Single-photon emitters are essential building blocks for next-generation quantum communication and computing protocols as they can be used as a quantum bit (qubit). The current breakthrough has solved a long-standing and practical hurdle of realizing deterministic single-photon emitters at room temperature. Previously, very low temperatures were necessary or the photons were hard to extract using other materials such as diamond, notes Menon. And, if single-photon emission did occur at room temperature, it happened at random locations.

The large energy gap of hBN stabilizes the emitters at room temperature within nanoscale regions created by substrate-induced deformation of the hBN. The smallest pillars, which were 75 nm in diameter, contained an average of about 2 emitters. The arrays can be manipulated via a combination of strain and external electrostatic potentials.

Source: https://www.ccny.cuny.edu/news/demand-room-temperature-single-photon-array-quantum-communication-breakthrough-ccny-physicists

REFERENCE:

1. Nicholas V. Proscia et al., Optica (2018); https://doi.org/10.1364/OPTICA.5.001128.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.