Sound waves create optical isolators well-suited to integrated photonics

Illinois researchers have demonstrated that sound waves can be used to produce ultraminiature optical diodes that are tiny enough to fit onto a computer chip. These devices, called optical isolators, may help solve major data capacity and system size challenges for photonic integrated circuits (PICs).

RELATED ARTICLE: Magnetization couples with a laser-induced sound wave, could be future hard-disk replacement

Isolators are nonreciprocal or "one-way" devices similar to electronic diodes. They protect laser sources from back reflections and are necessary for routing light signals around optical networks. Today, the dominant technology for producing such nonreciprocal devices requires materials that change their optical properties in response to magnetic fields, the researchers said.

In the journal Nature Photonics, the researchers explain how they use the minuscule coupling between light and sound to provide a unique solution that enables nonreciprocal devices with nearly any photonic material. However, the physical size of the device and the availability of materials are not the only problems with the current state of the art, the researchers said.

"There are several problems with using magnetically responsive materials to achieve the one-way flow of light in a photonic chip," said mechanical science and engineering professor and co-author of the study Gaurav Bahl. "First, industry simply does not have good capability to place compact magnets on a chip. But more importantly, the necessary materials are not yet available in photonics foundries. That is why industry desperately needs a better approach that uses only conventional materials and avoids magnetic fields altogether." Magnetic solutions are also bulky, have large optical loss, and don't have adequate bandwidth.

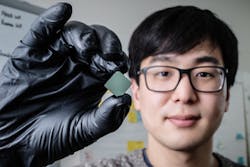

The new device is only 200 by 100 microns in size—about 10,000 times smaller than a centimeter squared—and made of aluminum nitride, a transparent material that transmits light and is compatible with photonics foundries. "Sound waves are produced in a way similar to a piezoelectric speaker, using tiny electrodes written directly onto the aluminum nitride with an electron beam. It is these sound waves that compel light within the device to travel only in one direction. This is the first time that a magnetless isolator has surpassed gigahertz bandwidth," Sohn said.

The researchers are looking for ways to increase bandwidth or data capacity of these isolators and are confident that they can overcome this hurdle. Once perfected, they envision transformative applications in photonic communication systems, gyroscopes, GPS systems, atomic timekeeping, and datacenters.

"In everyday life, we don’t see the interactions of light with sound," Bahl said. "Light can pass through a transparent pane of glass without doing anything strange. Our field of research has found that light and sound do, in fact, interact in a very subtle way. If you apply the right engineering principles, you can shake a transparent material in just the right way to enhance these effects and solve this major scientific challenge. It seems almost magical."

SOURCE: University of Illinois at Urbana-Champaign; http://illinois.edu/emailer/newsletter/157236.html

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.