Radiant Vision Systems lens allows in-headset display measurements for AR/VR devices

Radiant Vision Systems (Redmond, WA), a leading provider of visual test and inspection systems for lighting and display devices, announces the release of a new AR/VR lens system for Radiant Vision Systems ProMetric imaging photometers and colorimeters. The AR/VR lens measures the visual quality of near-eye displays (NEDs) inside virtual reality (VR), mixed reality (MR), and augmented reality (AR) headsets. The lens design simulates the size, position, and field of view of the human eye, featuring an aperture at the front of the lens to position the imaging system's entrance pupil within NED headsets at the same location as the human eye.

RELATED ARTICLE: Diving into emerging AR/VR markets—opportunities for optics

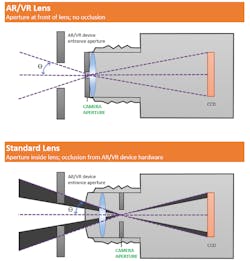

"In order to correctly assess the quality of near-eye displays as viewed by a human observer, the measurement system should replicate the ability of the human eye to receive immersive visual input, and at a similar distance from the display," says Doug Kreysar, Chief Solutions Officer at Radiant Vision Systems. "The challenge is that existing photometric measurement devices have been designed to evaluate more traditional displays like televisions and smartphones. In these systems, standard optical components position the aperture deep within the lens enclosure, limiting the camera's ability to capture the full angular field of view of the display without occlusion by NED headset hardware. The Radiant Vision Systems AR/VR lens, by comparison, features aperture characteristics that replicate the human eye in NED headsets, including an entrance pupil positioned directly at the headset eye lens. In addition, we are able to measure a large 120° field of view, suitable to measure advanced VR devices."

By mounting the AR/VR lens directly to a ProMetric imaging photometer or colorimeter, Radiant Vision Systems now offers the first solution for in-headset near-eye microdisplay measurement, including display technologies using LED, LCD, and OLEDs.

Standard tests include luminance, chromaticity, contrast, uniformity, mura (blemishes), pixel and line defects, and more. Unique tests for AR/VR display analysis include Slant Edge Contrast (for MTF measurement based on ISO 12233), Image Distortion (for distortion characterization), Image Retention/Sticking, and X, Y position reported in degrees.

The AR/VR lens is an optional mounting accessory for Radiant's 16- or 29-megapixel CCD-based ProMetric Y Imaging Photometer or ProMetric I Imaging Colorimeter. By mounting a lens directly to a ProMetric imaging photometer or colorimeter, the AR/VR lens measures NEDs as a turnkey, compact camera/lens solution that requires minimal setup and integration time, equipment, or expertise. The AR/VR lens can easily be removed and replaced with standard lenses for additional display measurement applications, such as testing displays outside of headset equipment or on the production line.

SOURCE: Radiant Vision Systems; http://www.radiantvisionsystems.com/news/radiant-announces-new-arvr-lens-measuring-near-eye-displays-within-headsets

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.