Blue LEDs speed radioactive isotope tracing for improved drug development

A revolutionary new technique to create radioactive molecules, pioneered in the lab of Princeton University (Princeton, NJ) chemistry professor David MacMillan, has the potential to bring new medicines to patients much faster than before. "Your average drug takes 12 to 14 years to come to market," said MacMillan. "So everything that we can do to take that 14- or 12-year time frame and compress it is going to advantage society, because it gets medicines to people--to society--so much faster."

RELATED ARTICLE: Protein-based photocatalyst uses blue light to disinfect water

Every potential new medication has to go through testing to confirm that it affects the part of the body it is intended to affect. "Is it going to the right place? The wrong place? The right place and the wrong place?" MacMillan asked. Tracing the path of a chemical that dissolves into the bloodstream presented a serious challenge, but one that radiochemists solved years ago by swapping out individual atoms with radioactive substitutes. Once that is done, "the properties of the molecule--of the drug--are exactly the same except that they're radioactive, and that means that you can trace them really, really well," MacMillan said.

But that introduced a new problem.

"Getting these radioactive atoms into the drug is not a trivial thing to do," he said. "People have developed long, sometimes month-long, two-month, three-month long sequences just to get a tiny amount of a substance with a few radioactive atoms."

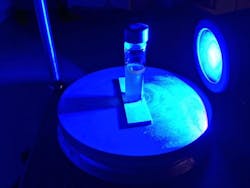

But now he and his colleagues have found a better way, drawing on their work using blue light-emitting diodes (LEDs) and catalysts that respond to light, known as photocatalysts. Their research was published online in the journal Science.

"It was a wacky idea! Fortunately, it worked," MacMillan said. "What we came up with was, if you shine light on them, and you have a photocatalyst, could these photocatalysts actually remove the non-radioactive atom and then install the radioactive atom?" They could.

MacMillan's technique uses "heavy water," which replaces the hydrogen (H) in H2O with tritium, a radioactive version of hydrogen that has an extra two neutrons per atom. "If you just let your drug sit in the radioactive water and shine light on it with a catalyst, the catalyst will remove the atom which is not radioactive--in this case it's hydrogen--and replace it with tritium," he said.

Suddenly, attaching one of these atomic labels takes hours instead of months, and the technique works on many kinds of frequently used compounds. The researchers have already tested it on 18 commercially available medicines, as well as candidates in the Merck drug discovery pipeline.

For compounds that don't need radioactive tags, the same one-step process can swap in deuterium, a version of hydrogen with only one extra neutron. These "stable labels" (with deuterium) and "radio labels" (with tritium) have countless applications, in academia as well as drug discovery.

This new method leverages the emerging field of photocatalysis pioneered at Princeton and applied it to yet another new field, MacMillan said. It has obvious financial value as well, but he waved that off. "No one's patenting any of this, because we want it to be available for everyone to use," MacMillan said.

SOURCE: Princeton University; https://www.princeton.edu/news/2017/11/09/leds-light-way-better-drug-therapies

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.