South Pole's 1 km IceCube is complete, tracks neutrinos with PMT grid

South Pole--On December 18, the IceCube Neutrino Observatory sank the last of 86 strings of photomultiplier tubes (PMTs) to a depth of almost two and a half kilometers in the ice at the South Pole, marking completion of the huge neutrino telescope.

Under construction since 2004, IceCube encloses a cubic kilometer of clear ice, beginning 1.5 km beneath the surface and extending downward another kilometer. The telescope has to be this big because neutrino collisions with matter are exceedingly rare: out of uncounted trillions of neutrinos constantly passing through the ice, IceCube will observe just a few hundred a day.

Seeing them at all is only possible because when neutrinos collide with the nuclei of oxygen atoms in the ice, they turn into energetic muons, moving in the same direction. Because these muons (and other debris from the collision) are moving faster than light can travel through ice, they radiate a shock wave of blue Cherenkov radiation visible to IceCube's photodetectors.

Tracking neutrinos with digital optical modules

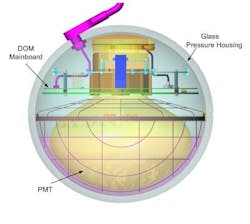

Sixty basketball-sized detectors are mounted on each IceCube string. Called digital optical modules (DOMs), their optical parts are PMTs (made by Hamamatsu Photonics; Hamamatsu City, Japan) that detect and amplify the Cherenkov radiation from passing muons. Electronics convert the PMT signals to digital form. The PMTs and circuit boards are housed together in transparent glass pressure vessels (see figure). Because the DOMs are arranged in a 3D grid, they can accurately track the path of a neutrino as it passes through the kilometer-sized cube of ice.

Many of the already-installed DOMs have been in service for years; built-in electronics have performed with astonishing dependability. Ninety-eight percent of IceCube's over 5,000 DOMs are working perfectly, and another one percent are usable—reassuring numbers, given that the DOMs now frozen in the ice will never be seen again.

"The DOMs are no more accessible than a space satellite in high orbit," says Spencer Klein, group leader for neutrino astronomy at Lawrence Berkeley National Laboratory (Berkeley, CA), "but they're a lot more reliable and extremely robust. They're also performing far above specifications, which called for them to be able to resolve the timing of Cherenkov-radiation flashes within 5 ns. Instead, their timing resolution is about 2 ns."

Integrated circuits sample the PMT signals at a 300 MHz rate and convert each sample to a digital value. Commercial digitizer chips couldn't be used because of power limitations, since the fuel to power IceCube (and all work at the South Pole) must be flown in from 900 miles away on ski-equipped planes. Even the allotted 5 W of power per DOM requires 10 planeloads of fuel a year.

IceCube is a unique observatory of the neutrino sky. It will study neutrinos created high in the atmosphere and search for neutrinos created in gamma-ray bursts, active galactic nuclei, the interaction of cosmic rays with the universe's background radiation, and the annihilation of dark-matter particles.

"With the completion of IceCube, the 1970s dream of building a kilometer-scale neutrino detector has finally become a reality," says Francis Halzen, a professor of physics at the University of Wisconsin-Madison and the IceCube Collaboration's principal investigator. "Finally science can start with a stable instrument that already yields neutrinos with unprecedented energy and statistics."

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.