Visible Semiconductor Lasers: Standardized multilaser modules enable comprehensive data sets in life sciences

Optically pumped semiconductor lasers (OPSLs) have enjoyed success in life-science applications such as confocal microscopy, DNA sequencing, and flow cytometry (see sidebar, "OPSLs and laser diodes"). The key trend we are seeing in the life sciences laser market—both original-equipment manufacturer (OEM) and end user—is the increasing use of standardized modules or subsystems that are targeted at a specific group of applications.

These light engines integrate lasers, optics, mechanics, and electronics in a solution optimized for the application. Specifically, these products offer guaranteed overall system performance, rather than just a particular set of bare laser output parameters. This article reviews three of the key application drivers behind this trend.

Market drivers in life-science instrumentation

Multiwavelength flow cytometry. Flow cytometry relies on fluorescent probes that are tagged to specific cells, antigens, or subcellular components (or that are expressed by genetic modification of the cells themselves). The cells are then made to flow in single file past one or more laser beams, and their fluorescence in different wavelength bands is measured by multiple photodetectors.

Users are looking for an increased number of laser excitation wavelengths so that cells can be characterized by a greater number of parameters (see Fig. 1). In addition, while complex multiparameter cytometry used to be performed primarily on large instruments, these same techniques are increasingly being deployed in the clinical environment. In these instances, size, cost, and time-to-market are more critical than ever, and instrument builders are consequently looking for laser engines with multiwavelength functionality. In short, they are looking to maximize performance and minimize risk in areas such as laser noise and pointing stability.

Multiwavelength microscopy. Fluorescence microscopy has been a major market for the range of laser wavelengths provided by OPSL technology, particularly the longer wavelengths that are now used to optimally excite the latest fluorophores. These include the mFruit series of fluorescent proteins and a host of new green-, yellow-, and orange-excited dyes originally developed for multiparameter flow cytometry applications. Moreover, confocal applications and the newer superresolution methods often use combinations of multiple fluorophores to permit a sample to be simultaneously mapped or probed for more than one type of structure or biochemical characteristic (see Fig. 2). In addition, there is increasing use of additional wavelengths for photostimulation in optogenetics. The challenge is to couple all these wavelengths into the microscope on an "as-needed" basis.Multimodal microscopy. Another key trend is the growing interest in combining different microscopy technologies to enable researchers to link molecular events to macroscopic behavior. Laser-based microscopy techniques such as confocal imaging are vital here because they can uniquely provide imaging with chemical specificity—for example, mapping the locations of different fluorescently labeled gene products, or visualizing areas of increased metabolic activity using calcium-ion (Ca2+) imaging. However, their spatial resolution is limited to >20 nm, even with superresolution techniques.

As a result, many life-science researchers are looking to combine fluorescence-microscopy information with data from other modalities that provide higher resolution, such as the atomic-force microscope (AFM) and the reflection electron microscope (REM). Ideally, all these modalities should be integrated in a single platform. This has led to mergers and acquisitions among instrument makers, and has resulted in OEM companies focusing on their core competencies such as fluidics, chemistry, signal processing, and software. The simplest and most cost-effective instrument development solution for these OEMs is to outsource photonic expertise.

Standardized modules with application-specific performance

Each new instrument and application has its own specific requirements, but clearly it is not cost-effective for instrument manufacturers to define a new custom engine in each instance. Instead, laser manufacturers are supporting this need with a new generation of standardized modules with only limited customization or configuration needed for each specific application. In short, the same plug-and-play functionality introduced to OPSLs in 2010 is now being extended to encompass complete laser engines or modules.

The goal with each application is to provide standard modules with the flexibility necessary to meet the needs of at least 95% of instrument platforms. The first success was in microscopy, where end users and instrument builders needed the ability to connect and interchange numerous visible laser wavelengths and powers. Coherent's OBIS Galaxy was developed to fulfill this need, allowing fiber-coupled lasers (from 405 to 640 nm) to be brought in or out of the system via threaded FC/UFC single-mode fiber connectors. This reduced the time needed to connect a new laser down to seconds, rather than the traditional hours for conventional fiber coupling. Because of the wide variety of laser wavelengths used in microscopy, this approach by necessity relied on using standalone smart lasers coupled into a central module.

However, in flow cytometry, the laser wavelengths are very standard-most multiwavelength instruments use 405, 488, and 640 nm, with 561 nm sometimes added to the mix. As a result, a new module for cytometry called CellX introduced in 2017 takes the standardized product concept to its conclusion by integrating up to four lasers inside the module. This integration also allows cost reduction through consolidation of hardware and electronics, for instance, by using a single laser controller board, common power, and I/O connector.

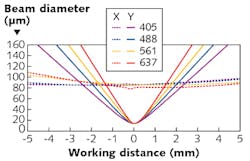

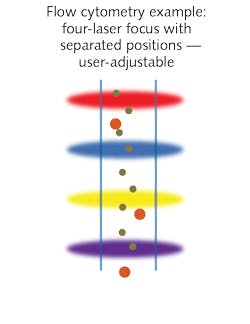

In multiwavelength flow cytometry, the total number of cell types discernable is maximized by correlating many different signals from multiple excitation (or light scatter) sources. To do this, the instrument needs to know whether fluorescence detected at, say, 550 nm is because of excitation at 405 or 488 nm. The most common way to achieve this is to arrange the focused laser beams as a staggered sequence of elliptical foci aligned with the flow stream, as shown in Fig. 1. The use of a trigger signal and time-delay gating allows for the correlation of sequentially generated signals from a single object into a single data packet. Thus, signal discrimination as a function of both emission wavelength selection and position in the flow stream is achieved.While providing for these common elements of flow-cytometry instruments, the OPSL module provides flexibility to customize laser beam parameters for specific instrument designs (see Fig. 3). Most importantly, the output optics for the four beams are all independently adjustable by the OEM integrator to optimize focus and to generate different sequences and spacings. The separation can be varied from zero (co-aligned) to ±250 μm—in addition, each of the four lasers is independently addressable and controlled through a standard USB connection.

OPSLs and laser diodes

Two complementary solid-state laser technologies service most of the life sciences market: the optically pumped semiconductor laser (OPSL) and the laser diode. Consequently, a key milestone was the development of smart, plug-and-play compact lasers having identical packaging, irrespective of their internal technology.

In an OPSL, a quantum-well-type indium gallium arsenide (InGaAs) chip is optically pumped by one or more laser diodes. By changing the size and stoichiometry of the quantum wells, and using harmonic conversion of the resulting output, the laser wavelength can be tailored over a wide range from 355 nm throughout the visible and into the infrared. In addition to wavelength scaling, the technology is power-scalable and power-adjustable because there is no thermal lensing as in crystal-based lasers. The large-area gain chip also naturally supports a TEM00 circular output beam.

Once limited to the red and blue, laser diodes are now available at several visible wavelengths. In general, they offer lower power than OPSLs, but conversely, their cost is lower and they can be directly modulated at even higher speeds of up to hundreds of megahertz. However, their highly divergent and asymmetric output beam means that several optics are required to create a collimated near-circular output beam.

The optimum choice of technology for a specific application depends on the wavelength and power level, as well as the required modulation speed and beam quality. Packaging both types in an identical plug-and-play format enables the optimum choice at each wavelength in every application, as well the capability to select the right wavelength for the problem at hand.

About the Author

John Abbott

Director of LMC Sales, Coherent

John Abbott is Director of LMC Sales at Coherent (Santa Clara, CA).

Dan Callen

Product Line Manager, Direct-diode Laser Systems at Coherent

Dan Callen is Product Line Manager for Direct-diode Laser Systems at Coherent (Santa Clara, CA).

Matthias Schulze

Director of Marketing, OEM Components and Instrumentation at Coherent

Matthias Schulze is Director of Marketing, OEM Components and Instrumentation at Coherent (Santa Clara, CA).