University of Pittsburgh duo demos hydrogels that can be moved and shaped by light

Pittsburgh, PA--Researchers at the University of Pittsburgh have demonstrated that certain hydrogels (materials similar to what most contact lenses are made of) can undergo biomimetic shape transformations as a response to light.1 Their study is the first to show that these gels can be both reconfigured and controlled by light, undergoing self-sustained motion—a uniquely biomimetic behavior.

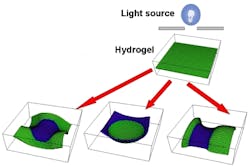

Lead author Anna Balazs and Olga Kuksenok, both at the Swanson School of Engineering, experimented with a recently developed type of hydrogel containing spirobenzopyran molecules. Such materials had been previously shown to form distinct 2D patterns on initially flat surfaces when introduced to varying patterns of light; they are hydrophilic (water-attracting) in the dark but become hydrophobic (water-repelling) under blue light. Balazs and Kuksenok anticipated that light could be a useful stimulus for tailoring the gel’s shape.

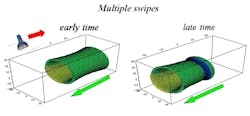

Using computer modeling, the two Pitt researchers demonstrated that the gels “ran away” when exposed to the light, exhibiting direct, sustained motion. The team also factored in heat—combining the light and local variations in temperature to further control the samples’ motions. Controlling a material with light and temperature could be applicable, Balazs says, in terms of regulating the movement of a microscopic conveyor belt or elevator in a microfluidic device.

“Consider, for example, that you could take one sheet of hydrogel and, with the appropriate use of light, fashion it into a lens-shaped object, which could be used in optical applications,” says Balazs.The researchers also demonstrated that the gels could undergo dynamic reconfiguration, meaning that, with a different combination of lights, the gel could be used for another purpose. Reconfigurable systems are particularly useful because they are reusable, leading to a significant reduction in cost.

The team will now study the effect of embedding microscopic fibers into the gel to further control the shape and response of the material to other stimuli. Funding for the study was provided by the U.S. Department of Energy.

REFERENCE:

1. Olga Kuksenok and Anna C. Balazs, Advanced Functional Materials, first published online 31 July 2013; doi: 10.1002/adfm.201203876.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.