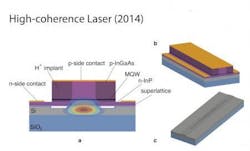

IMAGE: The new laser developed in Amnon Yariv's laboratory includes a layer of silicon, which does not absorb light--a quality important for laser purity. (Image credit: Amnon Yariv/Caltech)

Pasadena, CA--Research published in a Proceedings of the National Academy of Sciences paper entitled "High-coherence semiconductor lasers based on integral high-Q resonators in hybrid Si/III-V platforms" describes a new laser developed by a research group at Caltech that holds the potential to increase by orders of magnitude the rate of data transmission in optical-fiber networks. For light to carry the vast amounts of information--approximately 10,000 times more bandwidth than microwaves--the laser light needs to be as spectrally pure and as close to a single frequency as possible. Today's worldwide optical-fiber network is still powered by a laser known as the distributed-feedback (DFB) semiconductor laser, developed at Caltech in the mid 1970s in Amnon Yariv's research group; the new laser radically improves on these legacy DFB designs.

The old S-DFB laser consists of continuous crystalline layers of materials called III-V semiconductors--typically gallium arsenide and indium phosphide--that convert into light the applied electrical current flowing through the structure. Once generated, the light is stored within the same material. Since III-V semiconductors are also strong light absorbers--and this absorption leads to a degradation of spectral purity--the researchers sought a different solution for the new laser.

The high-coherence new laser still converts current to light using the III-V material, but in a fundamental departure from the DFB laser, it stores the light in a layer of silicon, which does not absorb light. Spatial patterning of this silicon layer--a variant of the corrugated surface of the DFB laser--causes the silicon to act as a light concentrator, pulling the newly generated light away from the light-absorbing III-V material and into the near absorption-free silicon.

This newly achieved high spectral purity--a 20 times narrower range of frequencies than possible with the DFB laser--could be especially important for the future of fiber-optic communications. Originally, laser beams in optical fibers carried information in pulses of light; data signals were impressed on the beam by rapidly turning the laser on and off, and the resulting light pulses were carried through the optical fibers. However, to meet the increasing demand for bandwidth, communications system engineers are now adopting a new method of impressing the data on laser beams that no longer requires this "on-off" technique. This method is called coherent phase communication.

In coherent phase communications, the data resides in small delays in the arrival time of the waves; the delays--a tiny fraction (10-16) of a second in duration--can then accurately relay the information even over thousands of miles. The digital electronic bits carrying video, data, or other information are converted at the laser into these small delays in the otherwise rock-steady light wave. But the number of possible delays, and thus the data-carrying capacity of the channel, is fundamentally limited by the degree of spectral purity of the laser beam. This purity can never be absolute--a limitation of the laws of physics--but with the new laser, Yariv and his team have tried to come as close to absolute purity as is possible.

SOURCE: Caltech; http://www.caltech.edu/content/new-laser-faster-internet