PROJECTION DISPLAYS: Lasers inject new life into projection displays

BARRY SILVERSTEIN and ANDREW KURTZ

Ever since lasers were invented more than 50 years ago, cinematography professionals have aspired to use laser light sources to project images. In the early 1960s, visible lasers were used along with galvanometer scanning mirrors for beam steering; this type of setup could project cartoonlike images on a screen with motion that was perceived as continuous due to the persistence of the human eye. These systems typically used gas lasers-often helium-neon, with a red output and less than a watt of optical power.

The situation improved during the 1970s via upgrades in laser powers to tens of watts and the availability of multiple wavelengths from bulky krypton and argon-ion lasers; these lasers required significant electrical power, high-volume water cooling, and substantial maintenance. Along with these new high-power lasers came new laser-safety issues, in which audiences (and, when used outdoors, vehicles such as airplanes) needed protection from the high-brightness beams.

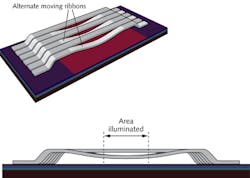

Alternate scanning methods and laser technologies were developed and demonstrated, but the next major milestone was the development of the grating light valve (GLV) by David Bloom at Stanford University in the mid-1990s. The GLV (which was further developed at Silicon Light Machines) diffracts incident laser light on a pixel-by-pixel basis; the diffracted orders are then filtered to distinguish between on- and off-state light. When a linear GLV array is imaged onto a screen and scanned in one direction, a 2D image results.

In the early 2000s, Eastman Kodak developed an alternative device, the grating electromechanical system (GEMS), which advantageously shifts the diffracted orders out of the array direction of the device.1 Using this device, a high-resolution, full-color imaging system including three linear pixelated modulators, an optical-parametric-oscillator (OPO) laser source, and a galvanometer scanner can project full 2D images (see Fig. 1). While this system provided compelling demonstrations, factors including the high cost of the lasers, the beam-quality requirements, laser speckle, and concern for laser-safety issues prevented commercial success.

In the meantime, the display industry continued innovating, developing HDTV-resolution flat-panel plasma and liquid-crystal displays (LCDs) to replace cathode-ray tubes (CRTs). Over time these technologies have matured, resulting in improved wall-plug efficiencies, high-brightness LED backlighting, and screen sizes reaching 100 in. diagonals.

In larger venues, film projection remains, but is gradually being replaced by digital projectors, using either liquid crystal on silicon (LCOS) or digital micromirror device (DMD) spatial light modulators (SLMs) having Digital Cinema Initiatives (DCI) studio specification "2K" (2048 × 1080 pixels) or "4K" (4096 × 2160 pixels) resolution. The modulators are illuminated by metal halide lamps or LEDs in lower-brightness noncinema applications and xenon lamps in large venues. These current displays are reliable and of high quality. So where do lasers fit?

Large image, small footprint

We believe that lasers will energize the large-projection-display field. While flat-panel displays meet most needs below sizes of 100 in., there are logistical and cost issues that gain relevance for display sizes larger than a 70 in. diagonal. Among these, the shipping, handling, and installation of such large pieces of glass present a difficult, costly, and labor-intensive operation. While contrast ratios, panel speeds, resolution, and even 3D capabilities have all improved substantially in flat-panel displays, ultimately the need to provide a large image with a smaller footprint presents opportunities.

This has been, for example, the driving force in the new picoprojector category: The ability to carry a 10–50 in. display in your pocket can be highly desirable. It can be expected that as projector size shrinks, energy efficiency (battery longevity) increases, and cost drops, picoprojectors will become more widely used. However, projectors relying on the current set of illumination sources have hit a design wall, which provides the juncture for a transition to lasers.

The most important limitation facing the projection industry is brightness. Displays are rarely too bright. In the cinema realm, where presentation quality is paramount, the environment is controlled; darkness accommodates the limitations of projection brightness as well as eliminates distractions for the viewers. Even in dark theaters, however, existing projectors tend to be too dim, according to many cinematographers and studio professionals. While conventional theaters typically show illumination levels between 11 and 14 foot lamberts (fL) in 2D presentations, many cinema experts would like to see screen-luminance levels exceed 100 fL.

In 3D presentation the situation is even worse, as many theaters struggle to hit 4 fL on their screens due to additional losses associated with 3D optics. This brightness level is a significant problem for the industry as viewers struggle to see details and fuse the two 3D images at these low levels.

The problem is that projectors with arc-lamp illumination are already fully optimized, with optics designed at the fastest speed possible to capture as much light and still deliver the required image resolution, contrast, and colors. At the same time, the arc lamps are built with a small arc gap to deliver a compromise between light output and a reasonable lifetime. In addition, the spatial light modulators are constrained to a small package and device size for reduced cost. Due to the resulting etendue and cost limitations, along with required quality parameters, optical-engine designers cannot provide more screen luminance without a source change.

This is true for high-end projectors like cinema projectors, where the optics are limited to f/2.4 optical systems, 6 kW arc lamps, and costly 1.4-in.-diagonal spatial light modulators. It is also true at the low end of the projection scale, where picoprojector size and low energy requirements dictate maximum efficiency at the smallest size. Therefore, modulators and optics need to shrink along with costs. The only way to do this is to capture more light and slow the system.

Lasers can do this. Lamps and LEDs emit in large angles (tens to hundreds of degrees) from relatively large areas (>1 mm), whereas solid-state lasers emit in small angles from small areas. As an example, 3 W green lasers from Necsel Intellectual Property (Sunnyvale, CA) have roughly 0.5° divergence angles and 0.1 mm emission diameters. This small source etendue allows optical designers to use the smallest SLMs and slow the optics for lower costs while providing optics that deliver higher contrast.

Furthermore, the narrow spectral bandwidths of lasers increase the projector color gamut, enabling an expanded color palette and better color reproduction. Most important, the projectors have a much higher optical efficiency and ability to deliver higher brightness at a lower energy usage (also lower heat generation). Another significant bonus of these lasers is their exceptionally long specified lifetimes-greater than 30,000 hours-which reduces operational costs for customers such as theaters and schools.

Lasers and 2D spatial light modulators

Rather than a modulated and scanned laser beam to provide images, the optimum system solution appears to be a combination of 2D SLMs as the imaging device and lasers as the illumination source.

While some companies, such as MicroVision (Redmond, WA), have created excellent picoprojectors using biaxial scanning galvanometers, the scanned laser sources have a very high brightness and short pulse time that creates an eye-damage risk for source fluxes above approximately 25 lumens. Using 2D SLMs with comparatively low-brightness laser light and long exposure times substantially decreases safety risks. Further, when properly combined with speckle-reduction techniques required to achieve quality images, the safety concern is reduced to something similar to that of conventional white-light projectors. This lower risk has allowed Kodak to receive a variance from the FDA to sell such laser projectors in cinema-type venues without individual site variances.2 In the future, it is likely that laws will be changed to further simplify regulations, which will make commercialization much more practical and simple.

Fortunately, lasers have finally reached a starting cost of lower than about $50 per optical watt in volume, with a demonstrated reliability that can enable this market to move forward quickly. Numerous suppliers, including well-known laser companies such as Mitsubishi (Tokyo, Japan) and Nichia (Tokushima, Japan), combined with lamp suppliers that have moved into the laser technology space, such as Ushio (Tokyo, Japan) and Osram Opto Semiconductors (Regensburg, Germany), as well as many small startup companies such as EpiCrystals (Tampere, Finland) and CQ Laser Technologies (Nanjing, China), will offer a great selection of lasers in the near future. This competition will drive innovation, commercialization, higher electrical-to-optical efficiencies, and cost reduction to the benefit of projector manufacturers and consumers.High-brightness demonstration

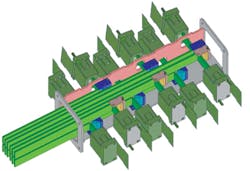

In early 2011, Kodak demonstrated an 11,000 lumen cinema-quality laser projector that provides exceptionally high-contrast 2D image quality, as well as designed-in bright 3D capability using passive glasses, which has kick-started this transition (see Fig. 2).3 The projector uses twelve 3 W lasers in each of the red, green, and blue channels, whose light is then made uniform through individual integrating bars and directed to respective DLP devices (see Fig. 3). Each color channel has its own simple polarization switcher to provide alternating polarization states for the left and right viewing 3D mode. The optics were slowed from f/2.4 to f/6.0, while the conventional prism combiner was replaced with dichroic plates to improve contrast and further reduce costs. Speckle reduction was accomplished throughout the machine using multiple techniques strategically placed to keep the optical efficiency high while reducing optomechanical complexity.Demonstration of this prototype projector showed that higher brightness, efficiency, contrast, and an equivalent cost structure can be achieved in comparison to conventional digital projectors, but with built-in passive 3D and substantially lower operational costs. In 2011, IMAX became the first company to exclusively license (in the "Digital Cinema" market) the technology for its highest-quality cinemas. Notably, this technology is extensible into the home theater, education, and business markets, where these same benefits can enhance projected-image quality and provide 3D while reducing cost through increased energy efficiency and longer light-source lifetimes.

REFERENCES

1. J.C. Brazas and M.W. Kowarz, "High-Resolution Laser-Projection Display System Using a Grating Electromechanical System (GEMS)," Proc. SPIE, 5438, 65 (2004).

2. FDA Variance, Number 2008V-0624 (December 2010); http://1.usa.gov/zvt1JR.

3. B.D. Silverstein et al., "A Laser-Based Digital Cinema Projector," SID Symp. Dig., 42, 326 (2011).

Barry Silverstein is the projection technology manager in Kodak's Entertainment Imaging division, Rochester, NY; e-mail: [email protected]. Andrew Kurtz is a senior research scientist at Kodak's Corporate Research and Engineering, Rochester, NY.