A group of researchers has taken a look at the use of double-negative-refractive-index (DNRI) metamaterials from the point of view of optical multilayer thin-film coating and filter designers. What they have discovered is that the replacement of, for example, the high-index layers in a multilayer thin-film optical coating with negative-index layers, drastically changes the optical properties, even allowing the existence of a type of multilayer Fabry-Perot (FP) cavity with a linear dependence of the overall round-trip phase in the cavity that is equal or very close to zero, a so-called "white" multilayer FP cavity. (The multilayer FP cavity, consisting of two multilayer reflectors sandwiching a thin-film center, is a standard approach to designing multilayer optical filters.)

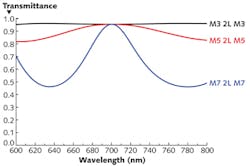

The researchers modeled negative refractive index in a simple way, simulating a negative-index material of positive thickness in a thin-film design program by substituting a replacement material having the same magnitude of thickness and index, but with negative rather than positive values. In three chosen designs (the structural terminology M3 2L M3, for example, signifies three multilayer stacks, a double low-index central layer, and then three more multilayer stacks) with different negative-index values, the wavelength dependence of the coating was tuned from low to lower to zero (blue, red, and black, respectively). Coatings containing negative-index layers could someday greatly broaden the capabilities of multilayer optical coatings, said the researchers.

Contact Michel Lequime at[email protected].