Visible and Near-IR Sensing: Plastic-optical-fiber-based ethanol sensor is simple, low-cost

Although water is certainly the most important liquid for use by humans, ethanol ranks high in importance, too, as it is used in the pharmaceutical, fuel, and other industries and appears as a contaminant in medications, foods, and drinks (and, of course, as an essential ingredient in some beverages). Consequently, ethanol detection is important for quality control, safety, and other purposes.

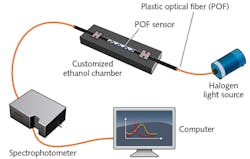

Researchers from University Putra Malaysia and University Kuala Lumpur (both in Selangor, Malaysia) have developed a simple fiber-optic sensor for this purpose that uses a broadband halogen visible and near-IR light source along with a spectrophotometer, the combination of which allows analysis over about a 400–1100 nm spectral range. The fiber itself is plastic, with its end coated with either carbon nanotubes (CNTs) or graphene oxide (GO). As a result, the device can potentially be made very cheaply and en masse.

Two types of carbon-based sensors compared

The experimental plastic optical fiber (POF) had a polymethyl-methacrylate (PMMA) core with a diameter of 980 μm and a fluorinated polymer cladding with a 20 μm thickness. The cladding from a 2 cm section along the length of the fiber was stripped off using acetone and a fine abrasive, leaving a length of exposed core that became the sensing region of the fiber. Examination under a microscope showed successful removal of the cladding without damaging the core.

The researchers added raw CNTs to a sulfuric acid solution, creating "functionalized" CNTs with differing amounts of carboxyl (COOH) molecules attached. The CNTs were then drop-cast onto the unclad fiber region and first heated to 70°C in the oven for 2 h, then dried at room temperature for 24 h.

For the GO-coated fibers, GO was first dispersed in deionized water and dispersed with ultrasound, then drop-cast onto the unclad fiber region and cured in a similar fashion to the fiber ends with CNTs. The researchers used a scanning electron microscope (SEM) to make sure the CNTs and GO were successfully deposited on the fiber sections. In addition, energy-dispersive x-ray (EDX) analysis ensured the presence of carbon and oxygen in the CNT and GO sensing layers.

The experimental setup was straightforward, with the halogen light source attached to one end of the fiber and the spectrophotometer to the other end (see Fig. 1). The exposed sensing region of the fiber was mounted in a chamber to which fluid could be added.

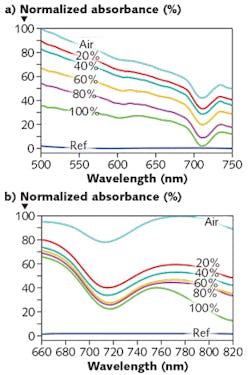

Testing with fluids consisting of varying amounts of ethanol in deionized water, the researchers observed that the absorbance of light decreased as the ethanol concentration increased, especially in specific spectral ranges: the 500 to 750 nm range for the CNTs and the 660-820 nm range for the GO (see Fig. 2). (Dips in the 700–720 nm and 700–730 nm absorbance spectral ranges for the CNT- and GO-coated fibers, respectively, were because of the sensing materials' optical properties.)The CNT-based sensor showed a much greater sensitivity compared to the GO-based sensor: 0.68/vol% vs. 0.19/vol%, or a fourfold-greater sensitivity. The researchers attribute this difference to the much greater surface area of the CNTs. In addition, the CNT-based sensor showed no saturation at high ethanol concentrations, in contrast to the GO-based sensor. The resolution of the CNT-based fiber was as fine as 0.2%.

REFERENCE

1. A. L. Khalaf et al., Opt. Express (2017); https://doi.org/10.1364/oe.25.005509.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.