Ultrafast lasers simplify fabrication of 3D hydrogel tissue scaffolds

Femtosecond lasers are improving fabrication of tissue scaffolds and implants without needing nonbiocompatible photoinitiators or chemical cross-linking materials typically used in 3D printing. Direct micropatterning leveraging multiphoton absorption (MPA) of ultrafast laser light has been demonstrated by Tufts University (Medford, MA) researchers within an elastomeric silk fibroin hydrogel formula that is transparent to visible light, allows initiation of MPA at low powers (a few nanojoules) without self-focusing, is biocompatible and biodegradable, and allows laser light to create 10- to 400-μm-diameter voids (with a 5 μm lateral resolution) over a large 3D volume in the hydrogel through penetration depths up to 1 cm—1.5 orders of magnitude deeper than other biocompatible materials.

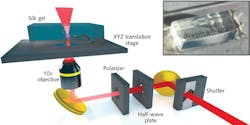

To fabricate complex features or voids within the hydrogel that function as tissue scaffolds for cell growth, the < 2 nJ output of an 810 nm, 80 MHz repetition-rate, 100 fs pulse-width femtosecond laser was input to a microscope objective and focused into the silk hydrogel fixed to a three-axis translation stage. Test patterns such as a 200-μm-diameter, two-turn helix and a blood-vessel-like branching structure beginning 300 μm deep and extending 100 μm in length were easily fabricated (in volumes up to 100 cm3) by scanning the stage at speeds between 50 and 100 μm/s. Typical fabrication time for the helix or vessel structure is around 1 hr., depending on the shape/size of object. Reference: M. B. Applegate et al., Proc. Nat. Acad. Sci., 112, 39, 12052–12057 (Sept. 29, 2015).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.