Printoptical Technology delivers economical 3D-printed arrays of optical elements

LUXeXcel (Goes, The Netherlands) Printoptical Technology uses modified wide-format industrial inkjet printers to economically and digitally fabricate optical structures (transparent prisms, lenses, and full-color graphics and textures) from CAD files via 3D printing methods without the need for expensive molding and tooling equipment. A piezoelectrically controllable print head jets an ultraviolet (UV)-curable photopolymer resin that is cured by UV lamps at the precise moment required to create optically smooth surfaces—no postprocessing required.

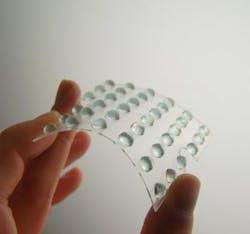

Printoptical-compatible polymers include polymethylmethacrylate (PMMA) and custom acrylate formulations; optical components in arrays with dimensions up to 60 cm × 100 cm are possible. "CAD-to-optic" Printoptical technology was used, for example, to fabricate 6 × 6 convex lens arrays on 500-μm-thick flexible polymer substrates for an LED lighting project. The technology can also fabricate prism structures with a 20-mm-long base and 1–2 mm height (30° and 60° top angles) with sharp-edged radii less than 200 μm, depending on the polymer used. LUXeXcel is working to have a new printer available in 4Q14 with increased speed, improved optical smoothness, and increased component-building height. Contact Peter Paul Cornellisen at[email protected].