Advances in Light Sources: Fiber lasers tune to the visible

ANGUS HENDERSON

Continuous-wave (CW) tunable lasers are widely used in scientific research requiring arbitrary wavelength access and ultranarrow linewidth. In particular, fields such as molecular spectroscopy and atomic physics can make use of the high spectral resolution and the ability to tune to specific wavelengths that are difficult to access with fixed frequency lasers. This allows the interactions of light with atoms and molecules to be investigated and manipulated with high precision.

Some of these needs can be met using inexpensive tunable diode lasers configured within an external cavity to allow precise tuning without mode hops. However, for applications requiring wide tuning, watt-level power, and good beam quality, other laser technologies must often be used.

The most commonly used "widely tunable" lasers are dye lasers and titanium sapphire (Ti:sapphire) lasers. Dye lasers allow wavelengths between 400 and 1000 nm to be generated using a number of different dyes. However, the availability of green-pump lasers and the shortage of other visible tunable lasers make them most useful in the yellow to red range. Between 700 and 1000 nm, Ti:sapphire lasers are more commonly used due to their greater ease of use and improved frequency stability compared to dye.

Dye and Ti:sapphire lasers have been available since the 1970s and 1980s, respectively. Although other tunable laser technologies have been demonstrated since then, it is only in the last few years, with the emergence of fiber lasers as pump sources, that some new classes of high-power tunable CW lasers have become commercially available as products.

Fiber lasers and fiber-laser-pumped tunable sources

Fiber lasers have transformed the capabilities of diode-pumped solid-state lasers in the past decade, taking diffraction-limited powers from tens of watts into the kilowatt regime. The ease of thermal management and the containment of the light within fiber have enabled new levels of power scalability and robustness when compared to conventional diode-pumped solid-state lasers.

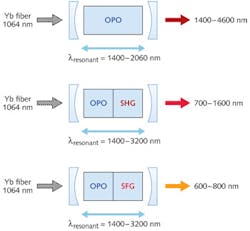

While fiber lasers themselves offer only limited wavelength tuning around center wavelengths near 1, 1.5, and 2 μm using ytterbium (Yb), erbium (Er), and thulium (Tm) dopants, respectively, they have proven to be useful pump sources for new classes of widely tunable laser sources. CW chromium zinc selenide (Cr:ZnSe) lasers pumped by thulium fiber lasers are now commercially available, providing over 10 W output within a range from 2 to 2.8 μm.1 Likewise, optical parametric oscillators (OPOs) pumped by ytterbium fiber lasers produce as much as 35 W output with wavelength coverage from 1.4 to 4.6 μm.2 These sources provide an important new research capability in the near to mid-infrared wavelength range where other lasers are very limited in performance.

Frequency conversion of fiber lasers to the visible

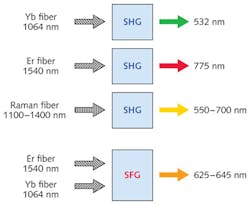

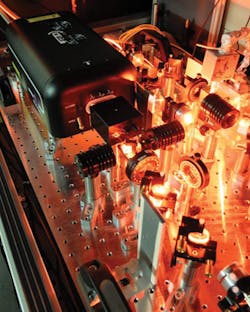

While fiber lasers have enabled new CW tunable sources in the infrared, they can also be used to generate visible wavelengths (see Fig. 1). The power, beam quality, polarization, and linewidth properties make fiber lasers ideal sources for frequency conversion by nonlinear optical materials. For high power conversion to the green, the second-harmonic generation (SHG) of Yb fiber lasers using lithium triborate has enabled up to 200 W of green with diffraction-limited output to be offered as a commercial product.3

Lower-power fiber lasers can take advantage of the high nonlinear drive of quasi-phase-matched nonlinear-optical (QPM-NLO) materials such as periodically poled lithium niobate (PPLN). Such materials can convert efficiently with as little as a few watts of CW input power.4

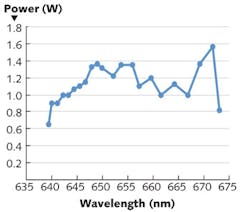

In addition to SHG to the green, promising demonstrations of red-wavelength generation have been performed by sum-frequency generation of two fiber lasers using Er and Yb dopants. By summing wavelengths around 1060 and 1540 nm in QPM-NLO materials, several watts of orange/red light have been generated in the range of 625 to 645 nm.5

In addition to these techniques, light in the visible range may be generated through SHG of Raman fiber lasers. Raman fiber lasers efficiently shift the operating wavelength of Yb fiber lasers into the 1100 to 1400 nm range. Frequency-doubling provides watt-level powers in the yellow to red range.

While several companies now offer frequency-doubled fiber lasers enabling access to a significant fraction of the visible range, these devices are typically configured to offer only a single wavelength.6 For many research applications where the user may wish to determine the optimum wavelength for a specific process, a fiber-laser-based widely tunable visible source would be highly advantageous.

CW OPOs for the visible

Optical parametric oscillators provide wider tuning than any other solid-state laser source. However, CW OPOs in the visible have proven difficult to realize due to the limited power-handling capabilities of QPM NLO materials at green wavelengths where capable pump lasers commonly operate. Significant absorption of green as well as generated visible wavelengths resonant within the OPO cavity lead to absorption and lensing of the nonlinear material. Ultimately, dephasing of the interacting beams spoils the efficiency of conversion.In comparison, the power-handling capability of PPLN and similar materials in the infrared is excellent. An alternative route to tunable visible output using an OPO is to use cascaded nonlinear conversion, that is, a device that uses an infrared-pumped OPO followed by SFG or SHG to generate tunable wavelengths shorter than that of the pump laser (see Fig. 2). While the second NLO process can be executed external to the OPO cavity, it can achieve maximum efficiency when taking advantage of high intracavity power at the resonant wave of the OPO. Intracavity cascaded OPOs with separate NLO crystals for each process have already been used to demonstrate red, green, blue, and UV outputs.7,8

Applications for tunable visible fiber lasers

While visible lasers are used for various applications including cinema projection, displays, materials processing, and biophotonics, many of these applications can be met using one of the many fixed-frequency approaches without the need for a highly precise wavelength. However, in scientific applications such as atom trapping, atomic clocks, sodium guide stars, and quantum optics, it is common that an exact wavelength with extremely narrow linewidth is required, which is not easily available from commercial fixed-frequency lasers. As such, high-power laser sources based on amplified single-frequency sources such as distributed-feedback (DFB) or distributed Bragg reflector (DBR) fiber lasers can enable new research capabilities.

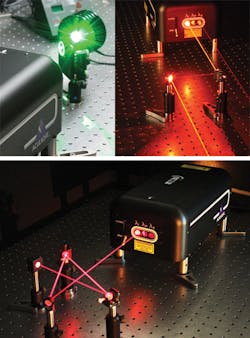

At the University of Darmstadt (Darmstadt, Germany), professor Thomas Halfmann and his group have made use of tunable visible light from an Argos OPO (see Fig. 5) for applications in solid-state quantum optics. Using a wavelength of slightly below 606 nm, they coherently drive an optical memory in a praesodymium-doped yttrium-orthosilicate (Pr3+:Y2SiO5) crystal. Recently, the group used Pr3+:Y2SiO5 to "stop" light and store an image in the crystal, reaching ultralong storage times of up to one minute. Such optical data storage devices with ultralong storage times are a key component for future applications such as information processing in quantum computers and quantum cryptography.Until recently, the required narrowband radiation at 606 nm with sufficient output power to drive Pr3+:Y2SiO5 was only available from dye lasers or from sum-frequency generation of two phase-locked lasers. The OPO-SFG approach enables a simpler all-solid-state setup for laser-driven optical memory.

At Rice University (Houston, TX), professor Tom Killian's research looks into the properties of ultracold atoms. In 2009 and 2010, his group created the first strontium Bose-Einstein condensates (BECs) and quantum-degenerate Fermi gases. They are currently developing techniques to promote the ultracold strontium atoms to highly excited "Rydberg" states, which interact with each other with strong, long-range forces due to the large dipole moments possible in these states. Dipolar interactions are predicted to lead to exotic phenomena such as supersolidity and three-dimensional solitons.

In the group's laboratory, an Argos OPO with output of 1 W at around 640 nm is frequency-doubled in an external cavity to provide more than 200 mW of UV light. The UV photons drive one step of the multiphoton excitation to the Rydberg states. The beam quality and high power from the OPO allow efficient generation of UV for these experiments, which is critical due to the small oscillator strengths for excitation.

Such users share a common desire to perform research with powerful all-solid-state visible lasers while moving away from older technologies such as dye lasers, which consume a great deal of time to maintain and operate, as well as presenting hazards in terms of the use of toxic dyes and liquid coolants.

Tuning throughout the visible

Future development of frequency-converted fiber lasers will require that development of nonlinear materials "catch up" with the progress in fiber lasers. While fiber lasers are already generating kilowatt-level powers, few nonlinear materials are currently able to handle hundreds of watts of visible and infrared power.

Quasi-phase-matched nonlinear materials are currently proven to handle perhaps only a few tens of watts in the visible. In addition, while QPM materials like PPLN are transmissive down to blue wavelengths, and although they have been used to generate wavelengths in the blue, the material absorption in this wavelength range is a limitation to power scaling. The performance and design flexibility of fiber lasers frequency-converted to the visible using QPM materials makes the prospect of further advances in widely tunable NLO sources driven by fiber lasers likely.

References

1. IPG Photonics HPTLM-Cr-ZnS/Se-2400-3000 Cr:Zn-Se lasers.

2. Lockheed Martin Argos BB-series CW OPO.

3. IPG Photonics' GLR-200 green fiber laser.

4. J. Kontur et al., Opt. Exp., 15, 20, 12882 (2007).

5. Hsiang-Yu Lo et al., "All-solid-state continuous-wave laser systems for ionization, cooling and quantum state manipulation of beryllium ions," arXiv:1306.3780 [physics.optics].

6. Quantel EYLSA 780 fiber laser; IPG Photonics RFL-630-20-M Raman red fiber lasers; MPB Communications VFL series visible Raman fiber lasers.

7. S. T. Lin et al., Opt. Exp., 18, 3, 2361 (2010).

8. K. Devi et al., Opt. Exp., 21, 21, 24829 (2013).

9. Lockheed Martin Argos Orange SF-series CW OPO.

Angus Henderson is staff scientist at Lockheed Martin Laser and Sensor Systems (formerly Lockheed Martin Aculight), 22121 20th Ave. SE, Bothell, WA 98021; e-mail: [email protected]; www.lockheedmartin.com/us/products/aculight.html.