Optical elements for any region of the electromagnetic spectrum are typically crafted from some sort of rigid material; while the fabrication approaches vary, the main obstacle to quick, flexible creation of an element is the fabrication process itself. This is a problem in particular for prototyping, where the experimenter would like to produce elements with custom qualities rapidly and without much fuss.

In the terahertz region, at least, this problem has been solved by a group of researchers at the Warsaw University of Technology (Warsaw, Poland) and the University of Savoie (Le Bourget du Lac, France), who have created binary phase-based diffractive lenses made of commercially purchased paper.1 The lenses in the experiment were laser-cut to a size of about 100 mm, although the diameter is, of course, one of the flexible parameters.

Paraxial and nonparaxial versions

The long wavelengths in the terahertz region are what make this approach possible, both in the tolerances needed for cutting the lens pattern and the allowable thickness (phase) variation in the paper. The researchers started out with two different types of paper: a green-tinted woodless chlorine-free paper from Antalis (Boulogne-Billancourt, France) with an areal density of 300 g/m2 and containing small metal flakes, and a conventional white glossy paper with a 250 g/m2 areal density.

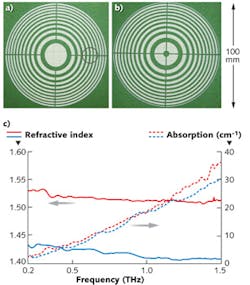

The optical characteristics of the paper were determined using time-domain spectroscopy (TDS); absorption varied almost linearly from about 2 to 30 cm-1 over a frequency range of 0.2 to 1.5 THz (with the green paper fairing slightly better over the entire range), while the refractive index ranged from 1.43 to 1.41 for the green paper and 1.53 to 1.51 for the white paper over the same frequencies. Two lens designs—one based on the paraxial lens equation and the other an asphere—were tested (see Fig. 1). The chosen focal length was 100 mm.

Because the green paper has a slightly lower absorption, it was used exclusively in the actual lens testing. The test setup consisted of a goniometer-mounted TDS instrument with two photoconductive antennas, with the receiver excited by ultrafast laser pulses through a fiber-optic dispersion-compensated system. The goniometric arm had a 15.9 cm length, with the lens at the center of rotation.

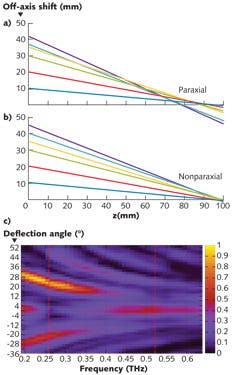

The TDS setup delivered a small beam that could not fill the lens aperture, and so a 15-mm-diameter aperture was used throughout the experiment; it and the beam were moved to different locations on the lens so that the local ray bundle at different locations could be tested. For each location, the researchers did a goniometric scan and a Gaussian fit to find the angle with maximal field amplitude. This allowed them to plot a type of ray trace for both the paraxial and nonparaxial lenses (see Fig. 2). As expected, the nonparaxial lens had better performance, creating a tight focus at 97 mm with a longitudinal aberration of less than 4 mm.To test the diffraction efficiency of the nonparaxial lens, the researchers isolated and integrated the light from the +1st-order diffraction (the focused light) produced by the area of lens defined by the 15-mm-diameter aperture. They recorded this data at frequencies ranging from 0.2 to about 0.65 THz.

The resulting value of each data point for a certain frequency was divided by the sum of intensities for the entire scan to produce a diffraction efficiency. At the design frequency of 0.26 THz, for which the phase retardation of the paper was about 180° (π), the diffraction efficiency was 37%. For comparison, the theoretical efficiency for the actual binary phase diffractive lens under the same conditions is 44%.

A plot of the data vs. frequency (see Fig. 2) shows the expected +1st-order maximum at a frequency of 0.26 THz (the curved yellow area at upper left). In addition, if the +1st-order intensity is followed to higher frequencies, it reaches a minimum at a frequency of 0.52 THz. This minimum is also expected, because the phase retardation of the paper at 0.52 THz (twice the 0.26 THz design frequency) is about 360° (2π) and thus very little diffraction is taking place.

The researchers also carried out a numerical simulation of the setup based on an off-axis modified convolution approach; the results agreed well with the data in Fig. 2.

More phase steps possible

The low f/# of 1, high diffractive efficiency, and good optical quality of the nonparaxial paper diffractive lens give it great potential for quick prototyping, and perhaps for other uses as well, although the paper lens does have a narrow bandwidth that excludes it from some applications.

Michał Makowski, one of the Warsaw University of Technology researchers, notes that the paper-element approach can be used for other types of terahertz optics such as prisms (which, in diffractive form, are gratings) and other, more complex designs. The usable frequency range for paper diffractive lenses strongly depends on the type of paper and the technical possibility of laser cutting of very fine stripes of paper, says Makowski, but he believes the optimal region is in the range of 0.1 to 0.5 THz.

Future work includes the creation of paper lenses with more phase steps; four steps and eight steps produce theoretical diffraction efficiencies of 81% and 95%, respectively.

REFERENCE

1. A. Siemion et al., Opt. Lett., 37, 20, 4320 (Oct. 15, 2012).

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.