SOFTWARE & COMPUTING: Simulating active photonic materials becomes easy

MARY POTASEK, EVGUENI PARILOV, and ANAND HARIHARAN

Many believe we are transitioning to a world where photonics will play the predominant role. While several relatively small companies have introduced optoelectronics and optical communications software, photonics is now at a stage where novel and more refined software is required to enable rapid growth and reduce time and costs.

Photonic devices are poised to replace many electronic devices as their physical limitations are reached. Even now, photonics is used in most fields, including optical communications, life sciences, medical devices, solid-state lighting, flat-panel displays, solar energy, information technology, and defense. To reduce multimillion dollar investments in equipment, facilities, and labor costs, it is necessary to advance and invent new computational algorithms with enhanced flexibility and accuracy. After many years of writing conventional software for photonics, we developed SimphoSOFT, which models light interactions with active materials directly from the user interface.

Simulation deficiencies

Most existing commercial optical simulation tools are based on many approximations in the underlying light-propagation models. Significant improvements in the treatment of nonlinear (intensity-dependent) optical effects, such as self-phase modulation stimulated scattering effects, have been added lately. For passive (non-gain) media, a bulk background absorption value is usually used, and for active media, a bulk gain parameter.

However, new technology demands faster and more accurate calculations. Many models do not take into account the microscopic details of the energy levels, the particle-particle interactions, or material-photon interactions. A lumped absorption cross-section, emission cross-section, and upper-state lifetime (based on values typically measured at spectral peak) are used to account for such interactions when available. These approximations lead to inaccurate predictions by the original models, especially at increasingly high optical intensity levels.

One limitation of traditional optical modeling software is that the code is written with a fixed configuration of photophysics interactions and a restricted number of accessible energy levels. If the types of physical interactions or the number of energy levels are changed, then the entire code for the model has to be updated or even rewritten. Furthermore, adding more interactions such as energy transfer, upconversion, singlet oxygen formation, and photobleaching, along with many different types of material components, may require writing a new program altogether.

The professional cost of writing typical code is in the range of $15–$25 per line of code; the average programmer can generate 35–50 lines of code per hour. Assuming that typical modeling software could contain a million lines of code, a major redevelopment of the software could cost millions of dollars. In addition, maintenance requirements for operational versions along with documentation requirements for legacy versions impose further costs.

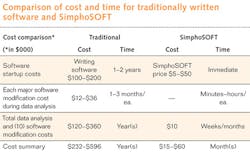

As an example of the costs of photonics modeling software, one of the authors (MP) has firsthand experience with writing traditional software and using SimphoSOFT. Two researchers worked on essentially the same problem to fit parameters to the same laser-matter experimental data: One wrote a C++ program and analyzed experiments using the traditional method of program writing and repeated modification to fit the data; the other used SimphoSOFT to analyze the data. The results were the same, but the time and costs varied significantly (see table at top of this page).

Transition modules

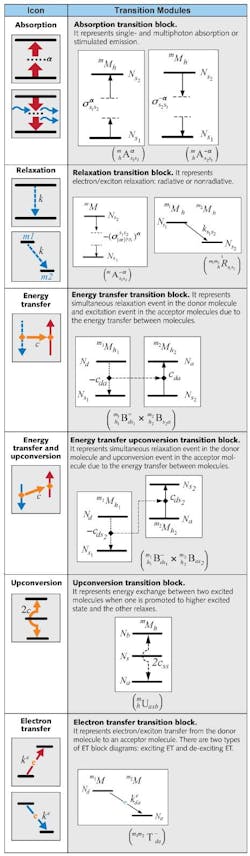

Several basic types of interactions govern the physics of laser-matter interactions, which when combined describe complex optical phenomena and can directly affect performance of devices made of active media. In the active media, photons can be absorbed and electrons/excitons are moved to different energy levels within the same media or to other media. Basic interactions include one or more photons absorbed and electrons moved to excited states, electrons decaying by radiative or nonradiative emission, and an electron decaying in one site/molecule and the resultant energy transferred to the excitation of an electron on another site/molecule. Other interactions include upconversion, downconversion, electron transfer, chemical reactions, cross-relaxation, photobleaching, and stimulated emission.

Our basic concept reduces the billions of possible photoactivated phenomena to the least common denominator, Simphotek's Transition Modules (TMs; see Fig. 1). Our mathematical method links these TMs to the underlying equations used to describe photoactivated interactions in nearly unlimited numbers of configurations.1-3Because the laser light is also changed by the photoactivated material, we also include a mathematical method of coupled equations to combine laser light changes due to the material and changes in the material due to the laser light. The algorithms can cover the entire electromagnetic spectrum, although to date we have only validated it against experiments in the UV, visible, and IR spectral regions.1,4-6

The software allows modeling complex interactions in real time by providing a graphical user interface (GUI) to build energy-level diagrams of arbitrary shape from graphical icons, representing the available TMs. The software automatically maps resulting diagrams to the underlying mathematical equations and solves them numerically with high accuracy.

This concept of graphical TMs forms the basis of a technology platform we are using to develop a series of CAD software products, enabling researchers, material designers, and product developers to simulate the interaction of laser light with optical materials. No currently available commercial or in-house software products have this capability.

Software solutions

Our first release in 2010 modeled laser transmission experiments based on a limited TM framework intended for use in 3D photonic media. We have generated several major upgrades and included new add-ons that can model energy transfer/upconversion/chemical reactions, multiple different laser wavelengths including pump-probe measurements, optimization of parameters, and z-scan experiments. The GUI is used to pass on to the kernel the configuration of the system as well as the associated parameters of the simulation, without any coding by the user.

On its backend, SimphoSOFT creates a numerical model that solves rate-propagation equations to find the beam profile and electron population dynamics at any propagation distance for a homogeneous material sample or a composite defined by the user. We are creating new TMs to extend our methods to areas such as semiconductors, metals, or metamaterials. While our first program uses a plane wave for the light field, the method easily incorporates other types of propagating fields such as waveguides, plasmonics, or scattering. A schematic of the graphical module-based approach illustrates its simplicity (see Fig. 2).The material to be modeled may be either single-layer or composed of multiple layers, with each layer having different species that can be subject to different photophysics interactions. The material can consist of gases, liquids, or solids in solutions, thin films, or many other structures. Several different types of photoactive materials may be combined together with varying concentrations and parameters.

There are auxiliary features intended to increase productivity. The simulation output consists of parameters that may be viewed as graphs, plots, and pictures, or as text files containing output data. Each simulation project maintains a record of all results.

Each material can be stored in the SimphoSOFT Library of Materials (LoM) for later use or can be shared. A list of material parameters from publications is available that allows users to simulate prior experiments and explore virtual material combinations.

SimphoSOFT models many materials and photophysical phenomena, such as one-two-or-more photon absorption with spontaneous or stimulated emission in chromophores and semiconductor quantum dots; energy transfer with upconversion (for example, Er:Yb-LiNbO3 and Tm:Ho-YLF); gain in Er:glass; photosynthetic electron transfer; stimulated-emission-depletion microscopy; upconversion and cross-relaxation (such as for Tm:YLF); combinations of photoabsorption, energy transfer, and photobleaching, such as for photodynamic therapy in Photofrin; and fluorescence emission intensities and spectral overlap as for flow cytometry. We plan to extend simulation capabilities by providing new product suites customized for different markets, including but not limited to the life-sciences market.

ACKNOWLEDGMENT

SimphoSOFT is a registered trade name of Simphotek Inc.

REFERENCES

1. E. Parilov, M. Potasek, J. Opt. Soc. Am., B23, 1894 (2006).

2. E. Parilov, M. Potasek, "Method, System and Software Arrangement for Determining an Interaction Between an Electromagnetic Radiation and a Material," 7,949,480 B2 (2011).

3. E. Parilov et al., "Determining the Interaction Between Electromagnetic Radiation and a Material by Utilizing Transition Modules," 2010/0037173 A1 (2010).

4. E. Parilov, M. Potasek, Proc. SPIE, 8240, 58 (2012).

5. K. Beeson, E. Parilov, M. Potasek, Proc. SPIE, 8257, 30 (2012).

6. M. Potasek, E. Parilov, Proc. SPIE, 8260, 18 (2012).

Mary Potasek is president, Evgueni Parilov is executive vice president, and Anand Hariharan was associate director of business development at Simphotek Inc., 211 Warren St., Newark, NJ 07103; e-mails: [email protected] and [email protected]; www.simphotek.com.