VERTICAL-CAVITY SURFACE-EMITTING LASERS: Electrically pumped GaN-based VCSELs emit blue and green at room temperature

Scientists at Nichia Corp. (Anan, Japan) have demonstrated the first electrically pumped indium gallium nitride/gallium nitride (InGaN/GaN)-based blue- and green-emitting vertical-cavity surface-emitting lasers (VCSELs). The blue VCSEL has a threshold current of 1.5 mA, a threshold voltage of 3.3 V, and emits 0.70 mW of continuous-wave (CW) light at 451 nm, while the green version has as 22 mA threshold current, a 6.3 V threshold voltage, and emits pulsed light with a peak power estimated to be greater than 0.80 mW at a 503 nm wavelength. Both lasers operate at room temperature. In general, VCSELs are low in cost when mass-produced; blue- and green-emitting versions could someday help bring small photonics devices such as laser picoprojectors into wide use.

c-plane GaN substrate

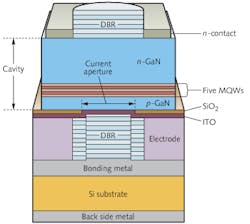

Both the blue and green VCSELs are based on a cavity defined by a pair of distributed Bragg reflectors (DBRs). The lasers are fabricated on c-plane GaN substrates and contain five InGaN/GaN multiple quantum wells (MQWs); they are bonded to silicon substrates (see figure). The blue and green lasers have emitting aperture diameters of 8 and 10 µm, respectively.

For GaN-based semiconductor lasers, a green output is always more difficult to achieve than a blue output; this is due to the higher percentage of indium required for green, which tends to create strain and defects in the crystalline structure. For this reason, the green Nichia laser does not yet emit CW light. This also explains the fact that the threshold current density for the green device, 28 kA/cm2, is so much higher than the 3.0 28 kA/cm2 value for the blue laser.

Because the spectral measurement resolution available to the Nichia lab was about 1 nm, the researchers did not observe line-narrowing upon lasing; however, they watched as the 499 nm below-threshold peak wavelength for the green laser jumped to 503 nm above threshold. They tentatively attribute this to a thermally induced change in refractive index, but note that the behavior of GaN-based VCSELs in this wavelength range is not well understood yet.

The near-field pattern of the blue VCSEL showed a small bright spot off to one side, while the green laser exhibited a uniform near-field pattern. Because the Nichia researchers had previously developed a violet GaN-based VCSEL, they have experience in near-field patterns at three different wavelengths, which has led them to speculate that some sort of inhomogeneity in material composition, current spreading, cavity length, or other flaw is causing the varied near-field patterns. (The previously created violet VCSEL had a threshold current of 7.0 mA under CW operation at room temperature, which was later reduced to 1.5 mA—the same as for the blue VCSEL.)

The Nichia researchers believe that the threshold current in the green region can be reduced, for example by using nonpolar or semipolar planes rather than the c-plane that was used in these devices. They note that much study of these new emitters must be done before they can be made reproducibly and with high performance.

REFERENCE

1. D. Kasahara et al., App. Phys. Exp., 4, 072103 (2011).

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.