Scientists have created new 2D nanostructured surfaces that appear as realistic 3D objects—including shading and shadows—using nanoengineering techniques. The research was carried out by King's College London alongside Rheinische Friedrich-Wilhelms-Universität Bonn, and is published in Nano Letters.

When light hits an object, the color, texture, and shape of the object affect how light is absorbed and reflected. By altering the surface to change how light is reflected, it is possible to manipulate how it appears to the eye. The researchers developed layered materials, incorporating precisely designed nano-features smaller than the wavelength of light, called metasurfaces. This allowed them to control how light is reflected in highly precise ways, so that a 2D surface reflects light just as a 3D object would.

RELATED ARTICLE: Optaglio introduces nanotechnology-based holograms that cannot be counterfeited

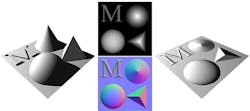

Borrowing a technique from 3D computer graphics called Normal Mapping, researchers encoded shadow effects into the image, creating 3D images more realistic than holograms or 3D cinema. As a proof of concept, the researchers fabricated a flat metasurface imitating lighting and shading effects of a 3D cube. The technique could have huge implications for TV screens and photography, as well as for security labels for protecting goods and banknotes from counterfeiting.

Professor Anatoly Zayats of King's College says, "Metasurfaces are amazing. They open up unprecedented freedom in directing and manipulating light. One might ultimately imagine a TV screen which appears exactly the same as you move around it, or a new movement of 3D art."

The ability to control light could bring new functionality to small camera lenses. A flat surface can be made to appear optically convex by designing appropriate metasurface properties. Future generations of smartphone cameras could use the tiny flat metasurfaces which mimic the properties of sophisticated curved camera lenses, allowing much greater control of angle and depth field. Metasurfaces could also replace heavy optical lenses in applications such as satellites, where weight and size have a big impact on efficiency.

Unlike holograms that require a coherent light source such as a laser to be viewed, these surfaces manipulate the reflection of normal light so they appear as a realistic 3D object in any light condition and from any angle. Existing holographic approaches rely on 'specular reflection' where the light coming from a particular direction is reflected in a unique outgoing direction, as with a mirror. In order to achieve dynamic light shading effects, a metasurface design involves 'diffuse reflection' that allows control of its scattering properties so that the image can be seen directly on it.

For the proof of concept, the researchers designed a cube using the normal mapping technique, which was encoded into the metasurface. When illuminated, the metasurface instantaneously "computes" how a 3D representation of the image should look and displays it.

SOURCE: King's College London; https://www.kcl.ac.uk/newsevents/index.aspx

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.