Numerical Modeling: Modeling metasurface lenses points way toward refining their performance

In 2011, Federico Capasso and members of his group at the Harvard University School of Engineering and Applied Sciences (SEAS; Cambridge, MA) reported that they had designed and fabricated a type of metasurface lens in which a subwavelength-spaced 2D array of metallic optical resonators—all generally "V" shaped, but with the angle of the V varying spatially—produced a corresponding variation of phase that allowed the device to serve as a focusing lens.1

Since then, Capasso's team, with the help of with researchers from other universities, has racked up an impressive roster of related technical achievements, including the creation of a high-efficiency achromatic metasurface lens that focuses over a wide angular range, a monochromatic (green) metasurface lens that produces two spatially separated images of the same object by separating the incoming light into its left- and right-circularly polarized components, and a metasurface lens used in a small handheld spectrometer that helps the instrument to achieve benchtop performance.

However, the numerical-modeling approaches used to design such metasurface lenses so far have assumed simple shapes (such as the "V") for the individual plasmonic nanoantennas because of the complexity of modeling nanoantennas with more-complicated shapes. As a result, scattering has been a problem for some of these metalenses.

Now, researchers from the Air Force Institute of Technology (AFIT; Wright- Patterson Air Force Base, OH) and Sandia National Laboratories (Albuquerque, NM) are using the COMSOL Multiphysics software package, a well-known suite produced by COMSOL (Burlington, MA), to numerically model several metasurface-lens designs, which were then fabricated and measured to see how well experiment matched simulation.2 To first establish confidence in the method, they have to date modeled variants of the original metasurface lens design (which use the V-antennas), thus paving the way for the modeling of future more-complex designs.

Cylindrical lenses modeled and fabricated

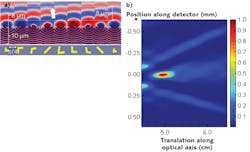

The modeled lens, which was simplified to be a cylindrical (1D) focusing lens, consisted of an array of 65-nm-thick gold V-antennas on a 10-μm-thick silicon substrate—the arms of the V-antennas have a width of 250 nm. The unit-cell periodicity was 6 μm, small enough to limit the diffraction orders to ±1 and large enough so that coupling between the antennas could be ignored. Mid-IR light at 5 and 8 μm wavelengths was modeled, and both near- and far-field data points were calculated (see figure).

The COMSOL finite-element method (FEM) calculations were performed for many variants of this metasurface lens; variations included focal lengths and, importantly, number of unique V-antenna elements. Next, 19 unique lenses and eight unique metasurfaces were fabricated at Sandia Labs with f-numbers ranging from 5 to 40, sizes on the order of 5 mm, and the number of unique V-antenna elements set at either 8 or 16. (The higher the number of unique elements there are, the less jagged the phase change is across the lens.)

One of the AFIT researchers, Capt. Bryan Adomanis, notes that, subsequent to their initial report presented at the COMSOL Boston 2016 conference, the researchers have measured a fabricated metasurface lens and validated focusing at the design wavelength (8 μm) and focal distance (5 cm).

"As far as we know, we are the only group which has attempted such a robust characterization," he says, "most notably in extending the number of unique elements from 8 to16 in order to smooth out the discretization."

Adomanis adds that the group is looking at implementing a genetic-algorithm technique to design a multilayer lens for improved polarization conversion and focusing efficiencies. "This has obvious fabrication challenges, and we will be working with our academic partners once the design has been fleshed out," he says.

REFERENCES

1. N. Yu et al., Science (Oct. 21, 2011); doi:10.1126/science.1210713.

2. B. Adomanis et al., "COMSOL Multiphysics software as a metasurfaces design tool for plasmonic-based flat lenses," Proc. COMSOL Conf., Boston, MA; www.comsol.com/2016-user-presentations.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.