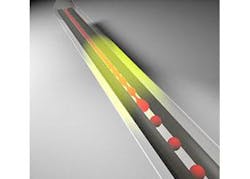

Connected to an electrical readout, a multimaterial fiber becomes a photodetector

Multimaterial optical fibers can combine electronic and photonic functions ine one fiber. A variation on this approach taken by scientists at the Massachusetts Institute of Technology (MIT; Cambridge, MA), the University of Central Florida College of Optics and Photonics (CREOL; Orlando, FL), and Indiana University Bloomington uses a polymer fiber as substrate for a semiconducting glass wire and two conducting wire electrodes; in the fiber-drawing process, the semiconducting wire breaks up into about 104 discrete microspheres (with diameters of on the order of 10 μm) per fiber, while the each conductors remain in one piece.

The chalcogenide semiconductor was amorphous arsenic pentaselenide (As2Se5) and the two electrodes were a carbon-black-filled polyethylene matrix; the fiber substrate was polycarbonate polymer. The fiber was drawn twice to reach the final configuration.

A photoresistive response to light from a Ti:sapphire laser with a wavelength of 760 nm and a power of 55 mW. In addition, optical resonances due to the linear array of microspheres were seen.

A photodetector with a slender fiber geometry, so unlike most photodetector shapes, could find use in novel applications.

REFERENCE:

1. Michael Rien et al., Nature Communications (2016); doi: 10.1038/ncomms12807

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.