ASU builds high-resolution gas-delivery nozzles using Nanoscribe 3D printers

3D printing today is a well-established technology for the fabrication of models or prototypes in various academic and industrial environments. However, the advantages of additive manufacturing provide also benefits for the production of end-use products. Among these advantages are cost-effective production of complex structures and functional integration for low-volume production down to a lot size of one.

RELATED ARTICLE: Additive manufacturing with NIR lasers forms micro-sized parts

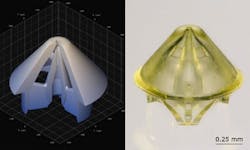

Described in Optics Express, researchers from Arizona State University (Tempe, AZ) demonstrated the benefits of high-resolution 3D printing for the fabrication of complex-shaped nozzles that are directly used for their experimental work.

For biological imaging using X-ray free-electron lasers, the use of gas dynamic virtual nozzles has proven to be valuable method for reliable sample delivery. However, the standard method of fabricating these nozzles manually represents a cumbersome and error-prone process.

The researchers successfully used a Photonic Professional GT from Nanoscribe (Eggenstein-Leopoldshafen, Germany) to consolidate several manual fabrication steps into one single automatic 3D printing step. The high-resolution 3D printing of polymer micro nozzles from CAD data enables the researchers to not only gain flexibility for design iterations but also to reduce the quality variances inherent in the standard manual fabrication method. As demonstrated by testing the jetting behavior, Nanoscribe says that these nozzles provide high-quality performance and have the potential to become the new standard in this field of research.

SOURCE: Nanoscribe; http://www.nanoscribe.de/en/media-press/newsletter/november-2016/3d-microprinting-new-standard-fabrication-nozzles/

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.