Trioptics to showcase precision goniometer, camera module measurement system at Optatec 2014

The PrismMaster goniometer performs prism angle measurements with 0.2 arcsec accuracy. It offers an enlarged field of view of the autocollimator, as well as increased sensitivity for measurement of ultrasmall prisms. For routine measurements in the production process, the system can be fed with prism data from a database. Its software prevents false measurements by discriminating internal from first surface reflections.

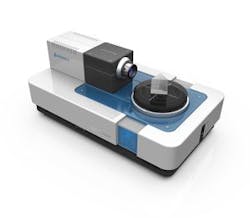

The ProCam Align camera module measurement system features the company's ProCam measurement technology, and can also be used to align the sensor with the camera optics in up to six degrees of freedom with submicron accuracy. The components are focused, moved, tilted, and rotated to one another during one alignment cycle. An integrated bonding and curing solution ensures an automated procedure for producing high-quality modules in serial production. The software stores all measurement data to ensure the traceability of the process.Optatec booth number: D20To Learn More:Contact: TriopticsHeadquarters: Wedel, GermanyProduct: PrismMaster goniometer and ProCam Align camera module measurement systemKey Features: PrismMaster: 0.2 arcsec accuracy; ProCam Align: Alignment with six degrees of freedomWhat Trioptics says: View more information on the PrismMaster and the ProCam Align.View More Products Locate a vendor or system integrator in our Buyer's Guide.Share new products that you think are particularly interesting or helpful by contacting Lee Dubay, Associate Editor, Laser Focus World.