Stanford, CA--Engineers at Stanford University and the University of Pennsylvania (Philadelphia, PA) have used "plasmonic cloaking" to create an invisible photodetector. The device consists of silicon nanowires covered by a thin cap of gold. By adjusting the ratio of metal to silicon—a technique the engineers refer to as tuning the geometries—they capitalize on favorable nanoscale physics in which the reflected light from the two materials cancel each other to make the device invisible. Pengyu Fan is lead author of a paper describing the plasmonic device published online May 20th in Nature Photonics. He is a doctoral candidate in materials science and engineering at Stanford University working in professor Mark Brongersma's group. Brongersma, a Keck Faculty Scholar in the School of Engineering, is senior author of the study.

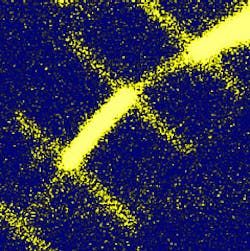

By carefully designing their device by tuning the geometries, the engineers have created a plasmonic cloak in which the scattered light from the metal and semiconductor cancel each other perfectly through a phenomenon known as destructive interference. The rippling light waves in the metal and semiconductor create a separation of positive and negative charges in the materials, or a dipole moment. The key is to create a dipole in the gold that is equal in strength but opposite in sign to the dipole in the silicon. When equally strong positive and negative dipoles meet, they cancel each other and the system becomes invisible.

"We found that a carefully engineered gold shell dramatically alters the optical response of the silicon nanowire," said Fan. "Light absorption in the wire drops slightly—by a factor of just four—but the scattering of light drops by 100 times due to the cloaking effect, becoming invisible."

"It seems counterintuitive," said Brongersma. "But you can cover a semiconductor with metal—even one as reflective as gold—and still have the light get through to the silicon. As we show, the metal not only allows the light to reach the silicon where we can detect the current generated, but it makes the wire invisible, too."

The engineers have shown that plasmonic cloaking is effective across much of the visible spectrum of light and that the effect works regardless of the angle of incoming light or the shape and placement of the metal-covered nanowires in the device. They likewise demonstrate that other metals commonly used in computer chips, like aluminum and copper, work just as well as gold. In digital cameras and advanced imaging systems, for instance, plasmonically cloaked pixels might reduce the disruptive cross-talk between neighboring pixels that produces blur. It could therefore lead to sharper, more accurate photos and medical images.

"We can even imagine reengineering existing opto-electronic devices to incorporate valuable new functions and to achieve sensor densities not possible today," concluded Brongersma. "There are many emerging opportunities for these photonic building blocks."

Brongersma lab alumnus Professor Linyou Cao and doctoral candidate Farzaneh Afshinmanesh contributed to this research. This work is a collaboration with Professor Nader Engheta and post-doctoral researcher Uday Chettiar from University of Pennsylvania.

SOURCE: Stanford University; http://engineering.stanford.edu/news/right-in-tune-engineers-devise-invisible-photodetector

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.